Cantilever Shafts / double offset / internal thread, ring groove / spanner flat

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Type | Material | Surface Treatment |

| FXJA | EN 1.1191 Equiv. | Black Oxide |

| PFXJA | Electroless Nickel Plating | |

| SFXJA | EN 1.4301 Equiv. | - |

Specifications

| Part Number | - | Y | - | F |

| FXHA12 PLXHA10 | - - | 5 20 | - - | F15 F35 |

| Part Number | Dg6 | 1mm Increment | M (Coarse) | a | V | H | W | d | m | n | Unit Price | ||||||

| Type | No. | Y | F | Ref. Dim. | Tolerance | FXJA | PFXJA | SFXJA | |||||||||

| FXJA PFXJA SFXJA | 6 | 6 | - 0.004 - 0.012 | 7~60 | 5~100 | M 3 | 5 | 8 | 10 | 8 | 5 | + 0.075 0 | 0.7 | 2 | |||

| 6A | 12 | 14 | 12 | ||||||||||||||

| 8 | 8 | - 0.005 - 0.014 | M 4 | 10 | 12 | 10 | 7 | + 0.090 0 | 0.9 | 3 | |||||||

| 8A | 14 | 16 | 14 | ||||||||||||||

| 10 | 10 | M 6 | 13 | 15 | 13 | 9.6 | 0 - 0.090 | 1.15 | |||||||||

| 10A | 18 | 20 | 17 | ||||||||||||||

| 12 | 12 | - 0.006 - 0.017 | 10~100 | M 8 | 15 | 17 | 14 | 11.5 | 0 - 0.110 | 4 | |||||||

| 13 | 13 | 16 | 18 | 15 | 12.4 | ||||||||||||

| 15 | 15 | M10 | 18 | 20 | 17 | 14.3 | |||||||||||

| 16 | 16 | 19 | 21 | 18 | 15.2 | ||||||||||||

| 17 | 17 | 20 | 23 | 20 | 16.2 | ||||||||||||

| 18 | 18 | 21 | 17 | 1.35 | |||||||||||||

| 20 | 20 | - 0.007 - 0.020 | 7~75 | M12 | 7 | 24 | 26 | 24 | 19 | 0 - 0.210 | |||||||

| 20A | M 8 | ||||||||||||||||

| 22 | 22 | M12 | 26 | 28 | 26 | 21 | 5 | ||||||||||

| 22A | M 8 | ||||||||||||||||

| 25 | 25 | M16 | 29 | 31 | 27 | 23.9 | |||||||||||

| 25A | M12 | ||||||||||||||||

| 30 | 30 | M20 | 34 | 36 | 32 | 28.6 | 1.65 | ||||||||||

| 30A | M16 | ||||||||||||||||

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Shaft Diameter (mm) | Material | Surface Treatment | Material | Thread Length Specifying Method | M (Coarse) | H Dimension (mm) | F (mm) | Y (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 Days | 10 | 6 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 3 | 10 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 6 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 3 | 10 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 6 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 3 | 14 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 6 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 3 | 14 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 8 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 4 | 12 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 8 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 4 | 12 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 8 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 4 | 16 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 8 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 4 | 16 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 10 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 6 | 15 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 10 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 6 | 15 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 10 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 6 | 20 | 5 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 10 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 6 | 20 | 5 ~ 100 | - | ||

| 1 | 3 Days | 10 | 12 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 8 | 17 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 12 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 8 | 17 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 13 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 8 | 18 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 13 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 8 | 18 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 15 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 20 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 15 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 20 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 16 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 21 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 16 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 21 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 17 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 23 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 17 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 23 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 18 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 23 | 10 ~ 100 | 7 ~ 60 | ||

| 1 | 3 Days | 10 | 18 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 10 | 23 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 20 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 26 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 20 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 26 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 20 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 8 | 26 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 20 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 8 | 26 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 22 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 28 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 22 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 28 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 22 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 8 | 28 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 22 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | Thread Length Fixed Type | 8 | 28 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 25 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 16 | 31 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 25 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 16 | 31 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 25 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 31 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 25 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 12 | 31 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 30 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 20 | 36 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 30 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 20 | 36 | 10 ~ 100 | - | ||

| 1 | 3 Days | 10 | 30 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 16 | 36 | 10 ~ 100 | 7 ~ 75 | ||

| 1 | 3 Days | 10 | 30 | Stainless Steel | Not Provided | EN 1.4301 Equiv. | - | 16 | 36 | 10 ~ 100 | - |

Loading...

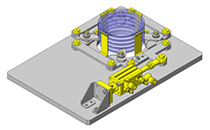

Example of Use

Basic information

| Shaft Retaining Method | Tapered (Screw) | Bearing Retaining Method | With Retaining Ring Grooves | Shoulder Shape | Stepped, Wrench Flats |

|---|---|---|---|---|---|

| Hardness | Hardness Not Spec-designed |

Configure

Basic Attributes

-

Shaft Diameter(mm)

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

-

Material

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

-

Thread Length Specifying Method

- Thread Length Fixed Type

-

M (Coarse)

- 3

- 4

- 6

- 8

- 10

- 12

- 16

- 20

-

H Dimension(mm)

-

F(mm)

-

Y(mm)

-

Type

- FXJA

- PFXJA

- SFXJA

-

Material

- Steel

- Stainless Steel

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 3 Days or Less

- 4 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry