- inCAD Library Home

- > No.000018 Test fixture for product aging

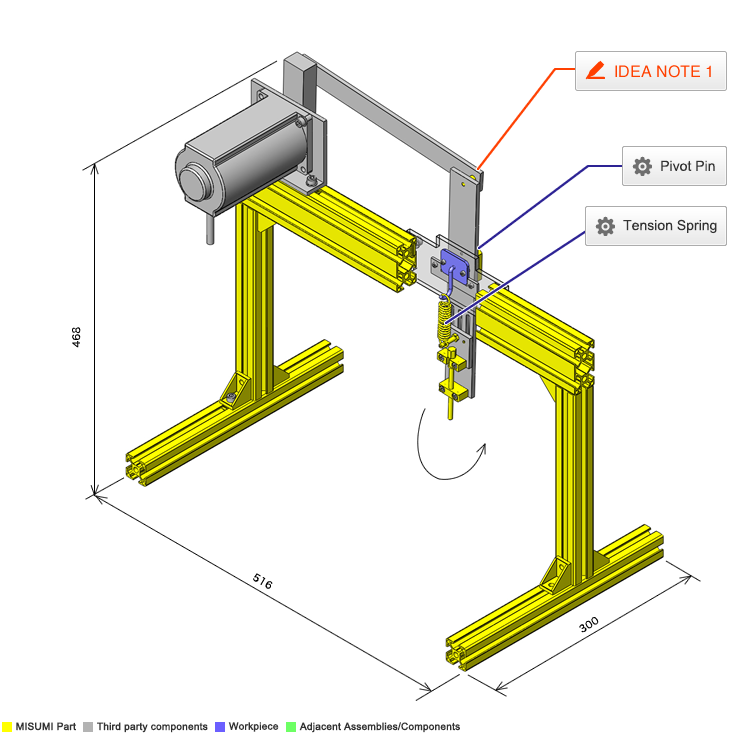

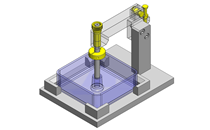

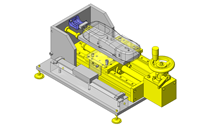

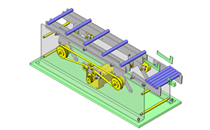

No.000018 Test fixture for product aging

20

20

Mechanism which converts rotary motion into reciprocating motion

Related Category

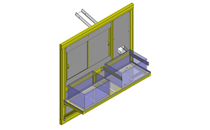

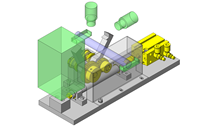

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Fixture to measure aging variations (dimensional changes over time, and cracking, etc.) by applying repeated loads. (Not to the extent of destruction)

Points for use

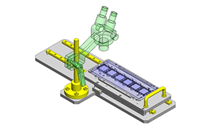

- Motor driven oscillating mechanism.

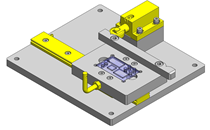

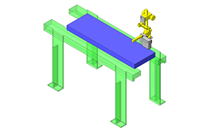

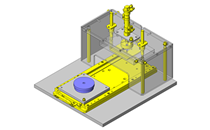

Target workpiece

- Levered lug

External Dims.: W40 x D30 x H3 (excluding the lever)

Workpiece weight: 5g

Design Specifications

Operating Conditions or Design Requirements

- Oscillates in ±45° range.

- External dims.: W516 x D300 x H468

Required Performance

- Tensile load: 60N

Spring constant: 4.13N/mm

Selection Criteria for Main Components

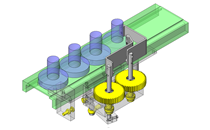

- Motor

- A motor is selected for automated oscillating motion.

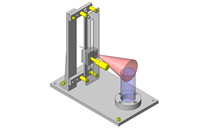

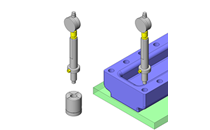

- Spring

- Spring selection makes applying arbitrary loadings possible.

Design Evaluation

Verification of main components

- Select an appropriate motor for oscillating motion.

- Motor speed

- Motor RPM (Ns) : 1800rpm

- Reduction ratio (i) : 1 / 50

- Rotation pitch circle diameter (Dp) : 156mm

- Link ratio: Approx. 1 / 3

- Speed (V)

V = Ns x (1 / 60) x i x π x Dp x 1 / 3

= 1800 x (1 / 60) x (1 / 50) x π x 156 x 1 / 3 = 98mm/s

- Torque

- Motor torque Tm = 3.33N・m

- Assumed load: F = 60N

- Link ratio: Approx. 1 / 3

- Fa = F * 1 / 3

- Load torque TL = (Fa x Dp) / (2 x 1000) = 60 x (1 / 3) x 156 / (2 x 1000) = 1.56N・m

Tm > TL, OK.

- Spring load

- Formula: Reaction force F = kx

- Assumed load: F = 60N

- Deflection under tension: x = 14.5mm

- Spring constant: k = 60 / 14.5 = 4.13N/mm selected

Other Design Consideration

- The spring load can be varied by moving the spring post in a slot located on the plate. An adjusting bolt is used for adjustments. The above configuration makes it easy to change the spring (varying the tension)

Explore Similar Application Examples

Page

-

/

-