Překládáme náš obchod do češtiny!

Protože však máme mnoho produktů a stránek, bude to nějakou dobu trvat. Mezitím bude náš katalog produktů k dispozici v angličtině. Děkujeme vám za trpělivost!

Podmínky filtrování

- Material

- Steel

- EN 1.1191 Equiv.

- EN 1.7220 Equiv.

- Stainless Steel

- EN 1.4301 Equiv.

- Stainless Steel, austenitic (high hardness

- Hardness

- Surface Treatment

- NA

- Surface Treatment Provided

- Black Oxide

- Electroless Nickel Plating

- D Tolerance

- Shaft Dia. D(mm)

- 4

- 5

- 6

- 8

- 10

- 12

- 13

- 15

- 16

- 17

- 18

- 20

- 22

- 25

- 30

- 35

- 40

- 50

- Length L(mm)[15–1000/0.1mm jednotek]

- Wrench Flats

- Tapped (Coarse / Effective Length: Nominal Diameter × 2) [M](mm)

- 2

- 2.6

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 24

- 30

- Tapped (Coarse / Effective Length: Nominal Diameter × 3) [MD](mm)

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- Tapped (Coarse / Effective Length: Nominal Diameter × 2) [N](mm)

- 2

- 2.6

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 24

- 30

- Tapped (Coarse / Effective Length: Nominal Diameter × 3) [ND](mm)

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- CAD

- 2D

- 3D

- Odhadované dodací dny

- Vše

- V rámci 4 pracovních dnů

- V rámci 6 pracovních dnů

- V rámci 8 pracovních dnů

Rotary Axes / Two-Sided Internal Thread / Optional Machining(Seznam čísel dílů: stránka 4)

Číslo dílu:

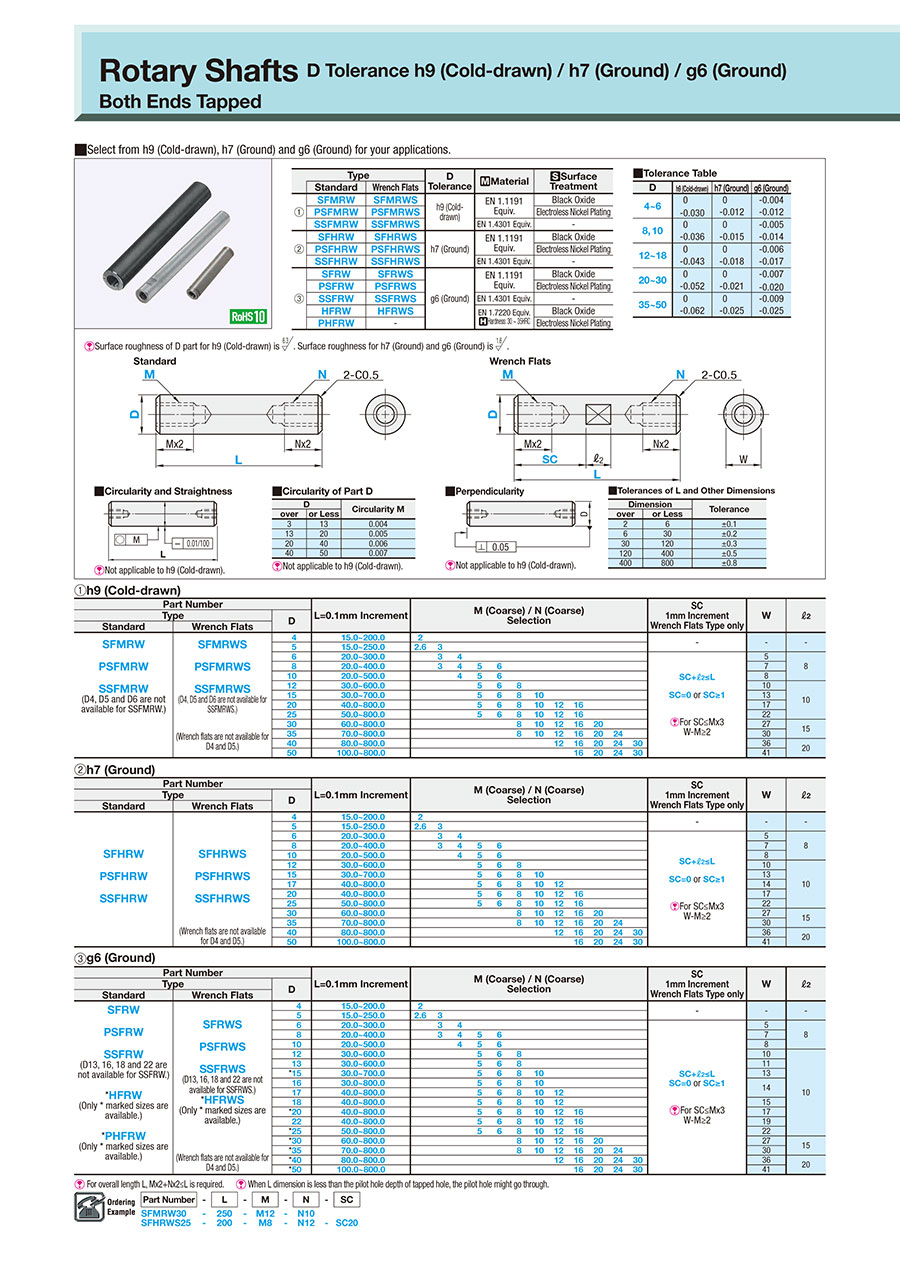

návrhy.Obrysový výkres a tabulka specifikací

Dimensional Drawing

■ Standard

■Wrench Flats

. Surface roughness for h7 (Ground) and g6 (Ground) is

. Surface roughness for h7 (Ground) and g6 (Ground) is  .

.■Tolerance Table

| D | h9 (Cold-drawn) | h7 (Ground) | g6 (Ground) |

| 4 to 6 | 0 | 0 | −0.004 |

| −0.030 | −0.012 | −0.012 | |

| 8·10 | 0 | 0 | −0.005 |

| −0.036 | −0.015 | −0.014 | |

| 12 to 18 | 0 | 0 | −0.006 |

| −0.043 | −0.018 | −0.017 | |

| 20 to 30 | 0 | 0 | −0.007 |

| −0.052 | −0.021 | −0.020 | |

| 35 to 50 | 0 | 0 | −0.009 |

| −0.062 | −0.025 | −0.025 |

■Circularity and Straightness

■Perpendicularity

■Circularity of Part D

| D | Circularity M | |

| over | or Less | |

| 3 | 13 | 0.004 |

| 13 | 20 | 0.005 |

| 20 | 40 | 0.006 |

| 40 | 50 | 0.007 |

■Straightness

| D | Straightness K |

| 2·2.5 | 0.1 |

| 3·4 | 0.03 |

| 5 | 0.02 |

| 6 or more | 0.01 |

■Tolerances of L and Other Dimensions

| Dimension | Dimension Tolerance | |

| over | or Less | |

| 2 | 6 | ±0.1 |

| 6 | 30 | ±0.2 |

| 30 | 120 | ±0.3 |

| 120 | 400 | ±0.5 |

| 400 | 1000 | ±0.8 |

| Type | D Tolerance | [M] Material | [S] Surface Treatment | ||

| Standard | Wrench Flats | ||||

| (1) | NSFMRW | NSFMRWS | h9 (Cold-drawn) | EN 1.1191 Equiv. | — |

| SFMRW | SFMRWS | Black Oxide | |||

| PSFMRW | PSFMRWS | Electroless Nickel Plating | |||

| SSFMRW | SSFMRWS | EN 1.4301 Equiv. | — | ||

| (2) | NSFHRW | NSFHRWS | h7 (Ground) | EN 1.1191 Equiv. | — |

| SFHRW | SFHRWS | Black Oxide | |||

| PSFHRW | PSFHRWS | Electroless Nickel Plating | |||

| SSFHRW | SSFHRWS | EN 1.4301 Equiv. | — | ||

| (3) | NSFRW | NSFRWS | g6 (Ground) | EN 1.1191 Equiv. | — |

| SFRW | SFRWS | Black Oxide | |||

| PSFRW | PSFRWS | Electroless Nickel Plating | |||

| SSFRW | SSFRWS | EN 1.4301 Equiv. | — | ||

| HFRW | HFRWS | EN 1.7220 Equiv. [H]Hardness: 30 to 35HRC | Black Oxide | ||

| PHFRW | — | Electroless Nickel Plating | |||

| AHFRW | AHFRWS | High Hardness Stainless Steel Hardness: 35HRC or More | — | ||

Specification Table

| Part Number | — | L | — | M | — | N | — | SC |

| SFMRW30 | — | 250 | — | M12 | — | N10 | ||

| SFHRWS25 | — | 200 | — | M8 | — | N12 | — | SC20 |

(1) h9 (Cold-drawn)

[ ! ] L ≥ M × 2 + N × 2 is required.

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

(2) h7 (Ground)

[ ! ] L ≥ M × 2 + N × 2 is required.

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

(3) g6 (Ground)

[ ! ] L ≥ M × 2 + N × 2 is required.

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

[NG] For HFRW and PHFRW, the upper limit for L dim. 35 to 50 is 800.

| Part Number | L 0.1 mm Increments | M (coarse), N (Coarse) Selection | SC 1 mm Increments Wrench Flats Type only | W | ℓ2 | ||||||||||||||

| Type | D | ||||||||||||||||||

| Standard | Wrench Flats | ||||||||||||||||||

| NSFMRW SFMRW PSFMRW SSFMRW (D4, 5, 13, 17, 18, or 22 is not available for SSFMRW.) | NSFMRWS SFMRWS PSFMRWS SSFMRWS (D13, 17, 18, or 22 are not available for SSFMRWS.) (Wrench flats are not available for D4 and D5.) | 4 | 15.0 to 200.0 | 2 | — | — | — | ||||||||||||

| 5 | 15.0 to 250.0 | 2 | 2.6 | 3 | |||||||||||||||

| 6 | 15.0 to 500.0 | 2.6 | 3 | 4 | SC+ℓ2 ≤ L SC = 0or SC ≥ 1 [ ! ] When SC ≤ M × 3, W−M ≥ 2 | 5 | 8 | ||||||||||||

| 8 | 15.0 to 500.0 | 2.6 | 3 | 4 | 5 | 6 | 7 | ||||||||||||

| 10 | 15.0 to 800.0 | 3 | 4 | 5 | 6 | 8 | |||||||||||||

| 12 | 15.0 to 900.0 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | |||||||||||

| 13 | 15.0 to 900.0 | 3 | 4 | 5 | 6 | 8 | 11 | ||||||||||||

| 15 | 15.0 to 1000.0 | 3 | 4 | 5 | 6 | 8 | 10 | 13 | |||||||||||

| 16 | 15.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |||||||||||

| 17 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | ||||||||||||

| 18 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | |||||||||||

| 20 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 17 | ||||||||||

| 22 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 19 | ||||||||||

| 25 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 22 | ||||||||||

| 30 | 20.0 to 1000.0 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 27 | 15 | |||||||||

| 35 | 70.0 to 1000.0 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | ||||||||||

| 40 | 80.0 to 1000.0 | 10 | 12 | 16 | 20 | 24 | 30 | 36 | 20 | ||||||||||

| 50 | 100.0 to 1000.0 | 12 | 16 | 20 | 24 | 30 | 41 | ||||||||||||

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

(2) h7 (Ground)

| Part Number | L 0.1 mm Increments | M (coarse), N (Coarse) Selection | SC 1 mm Increments Wrench Flats Type only | W | ℓ2 | ||||||||||||||

| Type | D | ||||||||||||||||||

| Standard | Wrench Flats | ||||||||||||||||||

NSFHRW SFHRW PSFHRW SSFHRW | NSFHRWS SFHRWS PSFHRWS SSFHRWS (Wrench flats are not available for D4 and D5.) | 4 | 15.0 to 200.0 | 2 | — | — | — | ||||||||||||

| 5 | 15.0 to 250.0 | 2 | 2.6 | 3 | |||||||||||||||

| 6 | 15.0 to 500.0 | 2.6 | 3 | 4 | SC+ℓ2 ≤ L SC = 0or SC ≥ 1 [ ! ] When SC ≤ M × 3, W−M ≥ 2 | 5 | 8 | ||||||||||||

| 8 | 15.0 to 500.0 | 2.6 | 3 | 4 | 5 | 6 | 7 | ||||||||||||

| 10 | 15.0 to 800.0 | 3 | 4 | 5 | 6 | 8 | |||||||||||||

| 12 | 15.0 to 900.0 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | |||||||||||

| 15 | 15.0 to 1000.0 | 3 | 4 | 5 | 6 | 8 | 10 | 13 | |||||||||||

| 17 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |||||||||||

| 20 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 17 | ||||||||||

| 25 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 22 | ||||||||||

| 30 | 20.0 to 1000.0 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 27 | 15 | |||||||||

| 35 | 70.0 to 1000.0 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | ||||||||||

| 40 | 80.0 to 1000.0 | 10 | 12 | 16 | 20 | 24 | 30 | 36 | 20 | ||||||||||

| 50 | 100.0 to 1000.0 | 12 | 16 | 20 | 24 | 30 | 41 | ||||||||||||

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

(3) g6 (Ground)

| Part Number | L 0.1 mm Increments | M (coarse), N (Coarse) Selection | SC 1 mm Increments Wrench Flats Type only | W | ℓ2 | |||||||||||||||

| Type | D | |||||||||||||||||||

| Standard | Wrench Flats | |||||||||||||||||||

| NSFRW SFRW PSFRW SSFRW HFRW (D15, 20, 25, 30, 35, 40, and 50 are available for HFRW.) PHFRW (D15, 20, 25, 30, 35, 40, and 50 are available for PHFRW.) AHFRW (Only * marked sizes are available.) | NSFRWS SFRWS PSFRWS SSFRWS HFRWS (D15, 20, 25, 30, 35, 40, or 50 is available for HFRWS.) AHFRWS (Only * marked sizes are available.) (Wrench flats are not available for D4 and D5.) | * | 4 | 15.0 to 200.0 | 2 | — | — | — | ||||||||||||

| * | 5 | 15.0 to 250.0 | 2 | 2.6 | 3 | |||||||||||||||

| * | 6 | 15.0 to 500.0 | 2.6 | 3 | 4 | SC+ℓ2 ≤ L SC = 0or SC ≥ 1 [ ! ] When SC ≤ M × 3, W−M ≥ 2 | 5 | 8 | ||||||||||||

| * | 8 | 15.0 to 500.0 | 2.6 | 3 | 4 | 5 | 6 | 7 | ||||||||||||

| * | 10 | 15.0 to 800.0 | 3 | 4 | 5 | 6 | 8 | |||||||||||||

| * | 12 | 15.0 to 900.0 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | |||||||||||

| 13 | 15.0 to 900.0 | 3 | 4 | 5 | 6 | 8 | 11 | |||||||||||||

| * | 15 | 15.0 to 1000.0 | 3 | 4 | 5 | 6 | 8 | 10 | 13 | |||||||||||

| * | 16 | 15.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |||||||||||

| 17 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | |||||||||||||

| 18 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | ||||||||||||

| * | 20 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 17 | ||||||||||

| 22 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 19 | |||||||||||

| * | 25 | 20.0 to 1000.0 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 22 | ||||||||||

| 30 | 20.0 to 1000.0 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 27 | 15 | ||||||||||

| 35 | 70.0 to 1000.0 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | |||||||||||

| 40 | 80.0 to 1000.0 | 10 | 12 | 16 | 20 | 24 | 30 | 36 | 20 | |||||||||||

| 50 | 100.0 to 1000.0 | 12 | 16 | 20 | 24 | 30 | 41 | |||||||||||||

[!] When L ≤ (M × 2 + pilot hole depth) + (N × 2 + pilot hole depth), the tapped pilot hole is through, and the priority is given to the large tap effective length, so the small tap effective length becomes shorter. (For MD and ND, L ≤ (MD × 3 + pilot hole depth) + (ND × 3 + pilot hole depth).)

[NG] For HFRW and PHFRW, the upper limit for L dim. 35 to 50 is 800.

| Coarse Thread Pitch | |

| M | Pitch |

| 2 | 0.4 |

| 2.6 | 0.45 |

| 3 | 0.5 |

| 4 | 0.7 |

| 5 | 0.8 |

| 6 | 1.0 |

| 8 | 1.25 |

| 10 | 1.5 |

| 12 | 1.75 |

| 16 | 2.0 |

| 20 | 2.5 |

| 24 | 3.0 |

| 30 | 3.5 |

Alterations

| Alterations Code | Alteration Details | Applicable Conditions | Ordering Example |

| KC | Keyway at One Location | KC, A = 0.1 mm Increments [ ! ] When the keyway position is less than 1 mm away from the end face, R is not applied. [ ! ] Key Length ≤ 100[ NG ] Not applicable when Shaft Dia. ≤ ø5 | SFHRW30-250-M10-N10-KC20-A10 |

| WKC | Keyways at Two Locations | WKC, C, K, E = 0.1 mm Increments [ ! ] When the keyway position is less than 1 mm away from the end face, R is not applied. [ ! ] Key Length ≤ 100[ NG ] Not applicable when Shaft Dia. ≤ ø5 | SFHRW30-250-M10-N10-WKC5-C20-K5-E10 |

| KZ | Keyway (1 Location (for 4th Location)) | KZ, Z = 0.1 mm Increments [ ! ] When the keyway position is less than 1 mm away from the end face, R is not applied. [ ! ] Key Length ≤ 100 [ NG ] Not applicable when Shaft Dia. ≤ ø5[ ! ] Applicable only when combined with both KC and WKC | SFHRW30-250-M10-N10-KC20-A10-WKC50-C10-K60-E10-KZ100-Z10 |

| FC | Set Screw Flat at One Location | FC, G = 1 mm Increments [ ! ]G ≤ 70 | SFHRW30-250-M10-N10-FC10-G3 |

| WFC | Set Screw Flats at Two Locations | WFC, J, W, V = 1 mm Increments [ ! ]J·V ≤ 70 | SFHRW30-250-M10-N10-WFC10-J15-W10-V20 |

| SFC | Set Screw Flat, 2 Set Screw Flats (Angle Specified) | SFC, SG = 1 mm Increments AG = 15° Increments [ ! ]SG ≤ 70 | SFHRW30-250-M10-N10-SFC10-SG3-AG120 |

| UC | Slit Cam Groove | UC = 1 mm Increments [NG] Not applicable when Shaft Dia. = ø2 or ø2.5 or when D ≥ 13 [NG] AHFRW or AHFRWS is not available | SFHRW10-250-M80-N8-UC10 |

| TA·TB | Retaining Ring Groove | TA, TB = 0.1 mm Increments [ ! ]2 ≤ TA·TB ≤ 150 | SFHRW30-250-M10-N10-TB10 |

| LKC | L Dimension Tolerance Change | L < 500···L±0.05 L ≥ 500···L±0.1 [ NG ] Not applicable when L ≥ 800 | SFHRW30-250-M10-N10-LKC |

| MD·ND | Tapped Depth | To specify any of these Alterations, replace M with MD or N with ND [NG] Not applicable when M = 2, 2.6, 24 or 30 | SFHRW30-250-MD10-ND10 |

[!] When combined with other alterations, ± 2 degree phase differential may occur. Provide 2 mm or more clearance between this alteration and others.

[ ! ] When multiple keyways or set screw flats are specified, they are added in the same plane. When the distance of the alterations are over 500 mm, ± 2 degree phase difference may occur.

Keyway Dimensions

|  | ||||||||||||||||||||||||||||||||||||||||||||||

[ ! ] If 3 keyways are required, use both KC and WKC.

[!] If 4 keyways are required, use KC, WKC, and KZ. (KZ is applicable only when combined with both KC and WKC)

[NG] Not applicable to D = 2 to 5.

[ ! ] The example below shows the keyway shape for the specs KC, WKC, K = 0, KC + A ≥ L and WKC + C + K + E > L.

[ ! ] Although keyway(s) and set screw flats are added in the same plane, ±2 degree phase differential may occur.

[ ! ] When the keyway position is less than 1 mm away from the end face, R is not applied.

[ ! ] When the keyway position is less than 1 mm away from the end face, R is not applied.

Detailed Retaining Ring Groove Dimensions for Rotary Shafts

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

[ ! ] An applicable retaining ring is included in the retaining ring groove.

(Reference Value) High Hardness Stainless Steel Center Hardness

| D | Center Hardness (HRC) |

| 3 | 35 or More |

| 4 | 35 or More |

| 5 | 35 or More |

| 6 | 35 or More |

| 8 | 35 or More |

| 10 | 30 or More |

| 12 | 30 or More |

| 15 | 30 or More |

| 16 | 30 or More |

| 20 | 25 or More |

| 25 | 25 or More |

Mechanical Properties (Reference Value)

High Hardness Stainless Steel Material Properties

(Unit: %)

| Material | Tensile Strength (Mpa) | Yielding Point (0.2% Proof Stress) (MPa) | Young's Modulus (GPa) | Transverse Modulus (GPa) | Poisson Ratio |

| EN 1.1191 Equiv. | 570 or More | 345 or More | 200 or More | 77 or More | 0.3 |

| EN 1.4301 Equiv. | 520 or More | 210 or More | 193 or More | 74 or More | 0.3 |

| EN 1.7220 Equiv. | 930 or More | 785 or More | 206 or More | 79 or More | 0.3 |

| High Hardness Stainless Steel | 1102 | 715 | 199 | 77 | 0.3 |

High Hardness Stainless Steel Material Properties

(Unit: %)

| C | Si | Mn | P | S | Ni | Cr |

| 0.15-0.25 | ≤ 0.50 | 7.5-9.5 | ≤ 0.05 | ≥ 0.12 | 1.5-3.0 | 13-15 |

Seznam čísel dílů

| Číslo dílu |

|---|

Jednotková cena (bez DPH)(Jednotková cena včetně DPH) | Standardní datum odeslání |

|---|

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

- ( - ) | 6 pracovních dnů |

Podrobné údaje

Základní informace

Náčrt a specifikace

App. Example