Překládáme náš obchod do češtiny!

Protože však máme mnoho produktů a stránek, bude to nějakou dobu trvat. Mezitím bude náš katalog produktů k dispozici v angličtině. Děkujeme vám za trpělivost!

- Stock

- Zobrazit pouze skladové položky

- Grade, Type

- Heat Resistant Urethane

- Abrasion Resistant Urethane

- Abrasion Resistant Urethane

- Vulkollan

- With or w/o Adhesive

- Thickness T(mm)

- 1

- 2

- 3

- 4

- 5

- 6

- 8

- 10

- 15

- 20

- 25

- 30

- Width A(mm)

- 3

- 5

- 10

- 20

- 30

- 40

- 50

- 80

- 100

- 300

- 500

[10–500/1mm jednotek] - Length B(mm)

- 300

- 500

[10–500/1mm jednotek] - Specifications

- Hole Machining

- CAD

- 2D

- 3D

Plates / PUR / abrasion resistant, temperature resistant / A68, A70, A90 (Seznam čísel dílů: stránka 12)

Číslo dílu:

návrhy.Obrysový výkres a tabulka specifikací

Dimensional Drawing

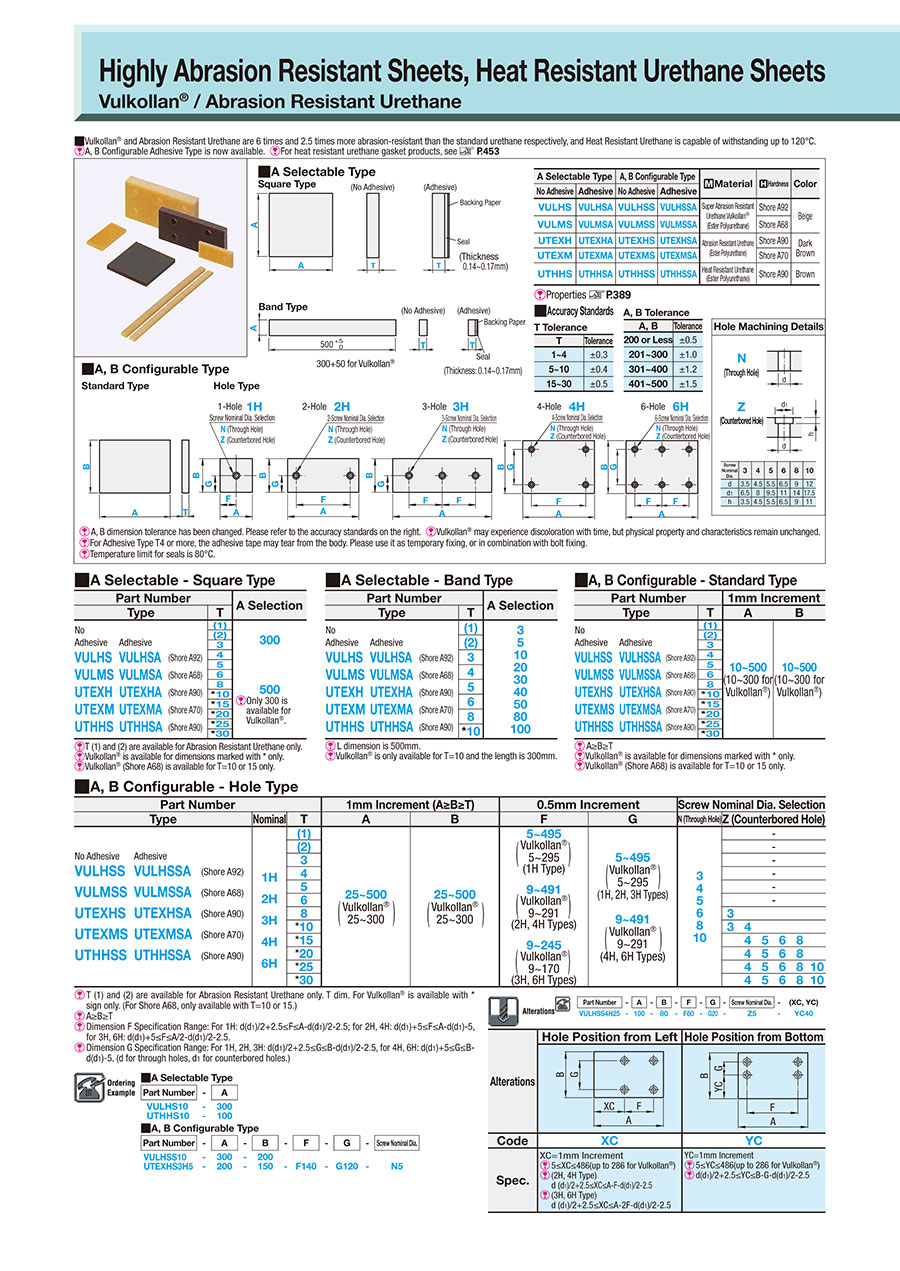

■A Selectable Type

Square Type

Band Type

(Thickness

0.14 to 0.17 mm)

For Vulkollan, 300 +5

0

(Thickness 0.14 to 0.17 mm)

Standard

[!]The adhesive tape may tear from the body. Please use it as temporary fixing, or in combination with bolt fixing.

[ ! ]Temperature limit for seals is 80°C.

| T | Tolerance |

| 1 to 4 | ±0.3 |

| 5 to 10 | ±0.4 |

| 15 to 30 | ±0.5 |

| A·B | Tolerance |

| 200 or Less | ±0.5 |

| 201 to 300 | ±1.0 |

| 301 to 400 | ±1.2 |

| 401 to 500 | ±1.5 |

| Hole Machining Details | |||||||||||||||||||||||||||||

N (Through Hole) Z (Counterbored Hole) |

| ||||||||||||||||||||||||||||

Product Specifications

| A Selectable Type | A, B Configurable | [M] Material | [H] Hardness | Color | ||

| No Adhesive | Adhesive | No Adhesive | Adhesive | |||

| VULHS | VULHSA | VULHSS | VULHSSA | Super Abrasion Resistant Urethane Vulkollan (Ester Polyurethane) | Shore A92 | Beige |

| VULMS | VULMSA | VULMSS | VULMSSA | Shore A68 | ||

| UTEXH | UTEXHA | UTEXHS | UTEXHSA | Abrasion Resistant Urethane (Ester Polyurethane) | Shore A90 | Dark Brown |

| UTEXM | UTEXMA | UTEXMS | UTEXMSA | Shore A70 | ||

| UTHHS | UTHHSA | UTHHSS | UTHHSSA | Heat Resistant Urethane (Ester Polyurethane) | Shore A90 | Brown |

| Item | Unit | Urethane | ||||

| Vulkollan® | Abrasion Resistance | Heat Resistance | ||||

| Hardness | Shore A | 92 | 68 | 90 | 70 | 90 |

| Specific Gravity | - | 1.26 | 1.2 | 1.2 | 1.13 | |

| Tensile Strength | MPa | 46.5 | 60 | 44.6 | 31.3 | 44.6 |

| Elongation | % | 690 | 650 | 530 | 650 | 530 |

| Specificb Volume Resistivity | (Ω・cm) | - | - | - | ||

| Heat Resistance | ℃ | 80(短時間120度) | 70 | 120 | ||

| Low Temp. Resistance | ℃ | -20 | -20 | -20 | ||

Specification Table

| Part Number | — | A |

| VULHS10 UTHHS10 | — — | 300 100 |

| Part Number | — | A | — | B | — | F | — | G | — | Screw Nominal Dia. |

| VULHSS10 UTEXHS3H5 | — — | 300 200 | — — | 200 150 | — | F140 | — | G120 | — | N5 |

| Part Number | A Selection | |||

| Type | T | |||

| No seal VULHS VULMS UTEXH UTEXM UTHHS | With seal VULHSA VULMSA UTEXHA UTEXMA UTHHSA | (Shore A92) (Shore A68) (Shore A90) (Shore A70) (Shore A90) | (1) | 300 500 [ ! ]Only 300 is available for Vulkollan |

| (2) | ||||

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 8 | ||||

| * 10 | ||||

| * 15 | ||||

| * 20 | ||||

| * 25 | ||||

| * 30 | ||||

[ ! ]Vulkollan is available for dimensions marked with * only.

[ ! ]Vulkollan (Shore A68) is available for T = 10 or 15 only.

| Part Number | A Selection | |||

| Type | T | |||

| No seal VULHS VULMS UTEXH UTEXM UTHHS | With seal VULHSA VULMSA UTEXHA UTEXMA UTHHSA | (Shore A92) (Shore A68) (Shore A90) (Shore A70) (Shore A90) | (1) | 3 5 10 20 30 40 50 80 100 |

| (2) | ||||

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 8 | ||||

| * 10 | ||||

[ ! ]Vulkollan is only available for T = 10 and the length is 300 mm.

| Part Number | 1 mm Increments | ||||

| Type | T | A | B | ||

| No Adhesive VULHSS VULMSS UTEXHS UTEXMS UTHHSS | With seal VULHSSA VULMSSA UTEXHSA UTEXMSA UTHHSSA | (Shore A92) (Shore A68) (Shore A90) (Shore A70) (Shore A90) | (1) | 10 to 500 (10 to 300 for Vulkollan ) | 10 to 500 (10 to 300 for Vulkollan ) |

| (2) | |||||

| 3 | |||||

| 4 | |||||

| 5 | |||||

| 6 | |||||

| 8 | |||||

| * 10 | |||||

| * 15 | |||||

| * 20 | |||||

| * 25 | |||||

| * 30 | |||||

[ ! ]Vulkollan is available for dimensions marked with * only.

[ ! ]Vulkollan (Shore A68) is available for T = 10 or 15 only.

| Part Number | 1 mm Increments (A ≥ B ≥ T) | 0.5 mm Increments | Screw Nominal Dia. Selection | ||||||||||||

| Type | Nominal | T | A | B | F | G | N (Through Hole) | Z (Counterbored Hole) | |||||||

| No Adhesive VULHSS VULMSS UTEXHS UTEXMS UTHHSS | Adhesive VULHSSA VULMSSA UTEXHSA UTEXMSA UTHHSSA | (Shore A92) (Shore A68) (Shore A90) (Shore A70) (Shore A90) | 1H 2H 3H 4H 6H | (1) | 25 to 500 (25 to 300 for Vulkollan ) | 25 to 500 (25 to 300 for Vulkollan ) | 5 to 495 (5 to 295 for Vulkollan ) (1H Type) 9 to 491 (9 to 291 for Vulkollan ) (2H, 4H Type) 9 to 245 (9 to 170 for Vulkollan ) (3H, 6H Type) | 5 to 495 (5 to 295 for Vulkollan ) (1H, 2H, 3H Type) 9 to 491 (9 to 291 for Vulkollan ) (4H, 6H Type) | 3 4 5 6 8 10 | — | |||||

| (2) | — | ||||||||||||||

| 3 | — | ||||||||||||||

| 4 | — | ||||||||||||||

| 5 | — | ||||||||||||||

| 6 | — | ||||||||||||||

| 8 | 3 | ||||||||||||||

| * 10 | 3 | 4 | |||||||||||||

| * 15 | 4 | 5 | 6 | 8 | |||||||||||

| * 20 | 4 | 5 | 6 | 8 | |||||||||||

| * 25 | 4 | 5 | 6 | 8 | 10 | ||||||||||

| * 30 | 4 | 5 | 6 | 8 | 10 | ||||||||||

[ ! ]A ≥ B ≥ T

[!]Dimension F Specification Range – 1H type selection: d (d1)/2 + 2.5 ≤ F ≤ A − d (d1)/2−2.5, when selecting 2H/4H type: d (d1) + 5 ≤ F ≤ A − d (d1)−5, when selecting 3H/6H type: d (d1) + 5 ≤ F ≤ A/2−d (d1)/2−2.5 is required.

[!]Dimension G Specification Range – 1H/2H/3H type selection: d (d1)/2 + 2.5 ≤ G ≤ B - d (d1)/2 - 2.5, when selecting 4H/6H type: d (d1) + 5 ≤ G ≤ B−d (d1)−5 is required. (d for through holes, d1 for counterbored holes.)

Alterations

| Alterations Code | Alteration Details | Applicable Conditions | Alteration Examples | |

| XC | Hole Position From Left | XC = 1 mm Increments | [ ! ]5 ≤ XC ≤ 486 (Up to 286 for Vulkollan) " ! " (2H, 4H Type): d (d1)/2 + 2.5 ≤ XC ≤ A-F-d (d1)/2-2.5 " ! " (3H, 6H Type): d (d1)/2 + 2.5 ≤ XC ≤ A-2F-d (d1)/2-2.5 | UTEXHS4H8-200-150-F120-G100-N5-XC55 |

| YC | Hole Position From Bottom | YC = 1 mm Increments | [ ! ]5 ≤ YC ≤ 486 (Up to 286 for Vulkollan) [ ! ] d (d1 )/2 + 2.5 ≤ YC ≤ B-G-d (d1)/2-2.5 | UTEXHS4H25-100-80-F60-G20-Z5-YC40 |

Seznam čísel dílů

| Číslo dílu |

|---|

Jednotková cena (bez DPH)(Jednotková cena včetně DPH) | Standardní datum odeslání |

|---|

- ( - ) | 7 pracovních dnů |

- ( - ) | 7 pracovních dnů |

- ( - ) | 7 pracovních dnů |

- ( - ) | 7 pracovních dnů |

Podrobné údaje

Základní informace

Náčrt a specifikace

General Information - Panels (polyurethane rubber, rubber, foam, felt)

_-_Sortiment.jpg)

Selection details of panels (polyurethane rubber, rubber, foam, felt)

- Material: polyurethane rubber (PU/PUR), heat-resistant polyurethane rubber, low-impact polyurethane rubber, abrasion-resistant polyurethane rubber, antistatic polyurethane, nitrile (NBR), chloroprene rubber (CR), polyethylene (EPDM), silicone (SI), fluorine (FPM), butyl rubber (IIR), natural rubber (NR), hard rubber, special synthetic rubber, polyurethane foam, head-insulating foam, polyethylene foam, low-rebound foam

- Thickness (mm): 0.5 to 50

- Width (mm): 3 to 500

- Length (mm): 10 to 2000

Description/Basics

Foam plates and rubber plates are provided for damping or for sound proofing. MISUMI offers these in various Shore hardening for a wide variety of tasks. Due to the variety of materials, different resistances to environmental influences are possible depending on the application. The foam plates reduce sound in machines and can reduce the sound emissions of a system. For more information on foam characteristics, follow this link.

Rubber plates or foam plates are also suitable in conveyor systems to absorb components to be transported at a dampened level or to protect them from damage as a lateral guide when the components bump into each other. Hard rubber panels or low-impact rubber or foam panels reduce the impact energy of the components. These minimize and lower the vibrations in an application.

In addition, MISUMI offers highly abrasion-resistant polyurethane (Vulkollan), which has an abrasion resistance that is six times higher than with conventional polyurethane.

Ceramic polyurethane plates contain ceramic particles. After machining, these can have a smooth surface despite low Shore hardness.

The polyurethane rubber plates are also available antistatically. The specific resistance of antistatic polyurethane plates prevents static charging. This prevents any damage to electronic components.

For applications with higher temperatures, MISUMI offers heat-resistant polyurethane rubber, which can withstand a temperature range of up to approx. ~120°C (see the product specifications for exact information).

MISUMI also offers low-friction and anti-friction rubber plates. Low-friction rubber plates are often used in the gentle component guide for belt conveyors and roller conveyors.

Felt plates have the property of absorbing or dispensing oil and other liquids via the capillary effect. This property can be used to remove, for example, excess oil on a belt conveyor.

In addition, MISUMI offers rubber plates and foam plates that are self-adhesive for simplified assembly. Furthermore, you will find double-adhesive tape for attaching rubber plates and foam plates.

Additional properties on foam panels and rubber plates can be found in the Properties PDF.

MISUMI also offers these products in a round shape as discs and sleeves made of rubber, natural rubber, foam and felt.

Application Examples - Panels (polyurethane rubber, rubber, foam, felt)

Application example

(1) Low-friction rubber plate (2) belt conveyor

Application example

(1) Vibration damping plate

Industrial Applications