Hex / Medium Accuracy / Threaded

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

| Material | Surface Treatment | Hardness | Type |

| EN 1.1191 Equiv. | Black Oxide | - | SRTAB |

| EN 1.1191 Equiv. | Hard Chrome Plating | Plating Hardness: 750HV ~ | SRTAR |

| EN 1.1191 Equiv. | Black Oxide | Treated Hardness: 45 ~ 50HRC | SRTAHB |

| EN 1.1191 Equiv. | Hard Chrome Plating | Treated Hardness: 45 ~ 50HRC Plating Hardness: 750HV ~ | SRTAHR |

| EN 1.4301 Equiv. | - | - | SRTASU |

| EN 1.4037 Equiv. | - | Treated Hardness: 50 ~ 55HRC | SRTAC |

Specifications

| Part Number | - | L | - | G | ||

| Type | B | |||||

| SRTAB | 8 | - | L20.00 | - | G6 | |

| Part Number | L 0.01mm Increment | G 1mm Increment | (C) | d | M (Coarse) | * Tightening Torque N•cm | Unit Price Threaded | ||||||

| Type | B | SRTAB | SRTAR | SRTAHB | SRTAHR | SRTASU | SRTAC | ||||||

| Threaded only | |||||||||||||

| SRTAB SRTAR SRTAHB SRTAHR SRTASU SRTAC | 6 | 10.00~50.00 | 0 or 2≤G≤d x 2 | 6.9 | 4 | M4 | 225 | - | |||||

| 7 | 8.1 | - | |||||||||||

| 8 | 15.00~50.00 | 9.2 | 5 | M5 | 461 | ||||||||

| 10 | 20.0 ~80.00 | 11.5 | |||||||||||

| 12 | 13.9 | 6 | M6 | 784 | |||||||||

| 13 | 15 | ||||||||||||

| 14 | 16.2 | ||||||||||||

| 17 | 19.6 | 8 | M8 | 1911 | |||||||||

| 19 | 21.9 | ||||||||||||

| 24 | 27.7 | 10 | M10 | 3783 | |||||||||

* The tightening torque (ref. value) for hardened products is strength class 8.8. (See technical data on >>P. 2297.) Not applicable when using locking materials or lock washers.

For full thread, specify a G dimension of 0 and NNC alteration.

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Material | Surface Treatment (Ø) | Heat Treatment | Hardness | Wrench Flats B (mm) | G (mm) | L (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 8 | 0 | 15 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 8 | 2 ~ 10 | 15 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 10 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 10 | 2 ~ 10 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 12 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 12 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 13 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 13 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 14 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 14 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 17 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 17 | 2 ~ 16 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 19 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 19 | 2 ~ 16 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 24 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Treated Hardness: 50 ~ 55HRC | 24 | 2 ~ 20 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 6 | 0 | 10 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 6 | 2 ~ 8 | 10 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 7 | 0 | 10 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 7 | 2 ~ 8 | 10 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 8 | 0 | 15 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 8 | 2 ~ 10 | 15 ~ 50 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 10 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 10 | 2 ~ 10 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 12 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 12 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 13 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 13 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 14 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 14 | 2 ~ 12 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 17 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 17 | 2 ~ 16 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 19 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 19 | 2 ~ 16 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 24 | 0 | 20 ~ 80 | ||

| 1 | 10 Days | 10 | Stainless Steel | Not Provided | Provided | Not Provided | 24 | 2 ~ 20 | 20 ~ 80 |

Loading...

Basic information

| Shape | Height Adjusting Pins | Height Tolerance | 0/+0.05 | Mounting Method | Threads |

|---|---|---|---|---|---|

| Tip Shape | Flat |

Configure

Basic Attributes

-

Surface Treatment(Ø)

-

Heat Treatment

- Provided

- Not Provided

-

Hardness

-

Wrench Flats B(mm)

-

G(mm)

-

L(mm)

-

Type

- SRTAB

- SRTAC

- SRTAHB

- SRTAHR

- SRTAR

- SRTASU

-

Material

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 10 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

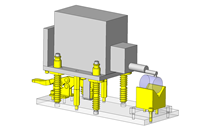

MISUMI Unit еxample related to this product

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry