Set collars / aluminium, stainless steel, steel / two-piece (SSCSPB30-15)

- Promotional pricing

- Volume Discount

Product Details:

Manufacturer part number: SSCSPB30-15

Brand: MISUMI

Price: 29.60 €

Delivery time: 5 Days

Technical Data:

[D] Inner Diameter (mm): 30 mm

O.D.: 55 mm

Width: 15 mm

Material: EN 1.4301 Equiv.

Surface Treatment: No Surface Treatment

- Order quantities extended (D-JIT)

- Stock

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

SSCSPB30-15

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Adjusting Rings

Available dimensions and tolerances can be found under the tab More Information .

| Type | Material | Surface Treatment | Accessory | ||

| Standard | Compact | Balanced Type | Hex Socket Head Cap Screw 2 pcs. | ||

| SCSP | SCSPJ | SCSPB | EN 1.1191 Equiv. | Black Oxide Coating | EN 1.7220 Equiv. |

| PSCSP | PSCSPJ | PSCSPB | Electroless Nickel Plating | EN 1.4301 Equiv. | |

| SSCSP | SSCSPJ | SSCSPB | EN 1.4301 Equiv. | - | |

| SCNPA | - | Aluminum Alloy 2000 series | - | ||

| SCNPAW | - | Clear Anodize | |||

The halves must remain in the same orientation as shipped when in use.

Further specifications can be found under the tab More Information .

| Part Number | - | B |

| SCSP10 SCNPA15 SCSPJ10 SCSPB17 | - - - - | 15 10 6 12 |

Adjusting Ring Selection Details

- Material: aluminum, plastic, stainless steel, steel

- Coatings: uncoated, burnished, anodized, stove-enameled, LTBC plated, nickel-plated

- Inner diameter: 3 to 100 mm

- External diameter: 7 to 150 mm

- Width: 5 to 36 mm

- Basic shapes: round, chamfered, offset, flattened on one side, flattened on both sides, cross hole

- Shaft fixing: clamping screw, with keyway, slotted clamping, with clamping lever, two-part, with hinge, wedge, quick-release, spring pin, internal thread

Overview of the various designs as PDF

Description/Basics

An adjusting ring is a connecting element that serves as a stopper or a locking device for linear shafts and rotary shafts.

The basic task of the adjusting rings, also called clamping rings, is the fixing by clamping a shaft at a predetermined position. The clamping ring can in this case serve as a stopper or as a positioning jig.

The adjusting ring enables to do without a shoulder on a shaft, as it can be mounted anywhere on a shaft due to the clamping connection. In addition to greater position flexibility, this feature reduces the production costs of the shaft and allows for a greater use of identical parts. Another advantage of the clamping connection of clamping rings is the continuous adjustment of the shaft or its attachments (e.g., ball bearings, timing pulley).

An adjusting ring can be used in applications for linear and rotary movements. For this purpose, MISUMI offers clamping rings in various designs.

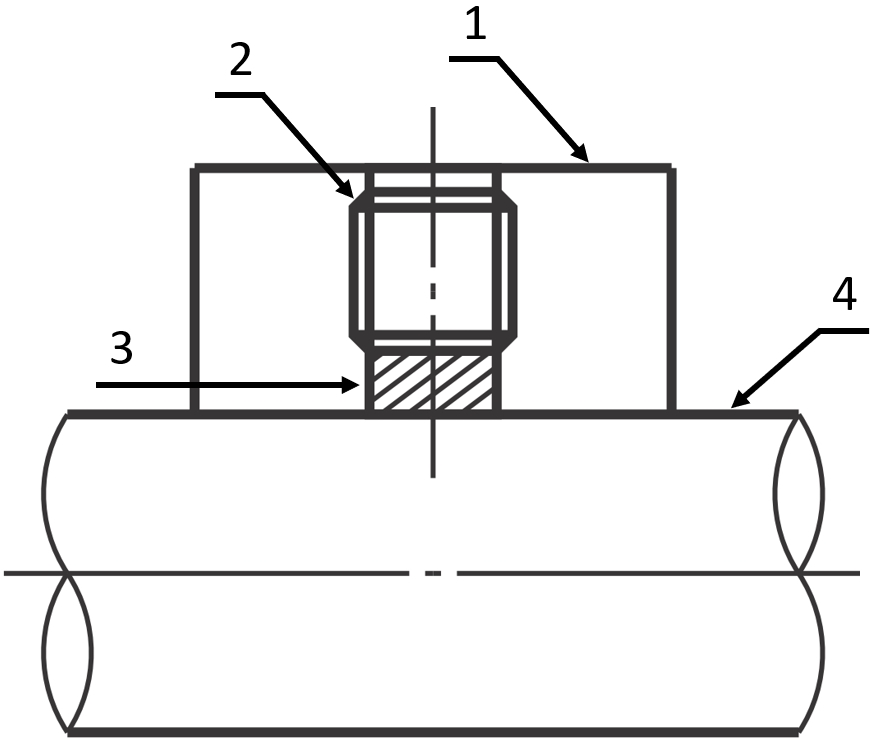

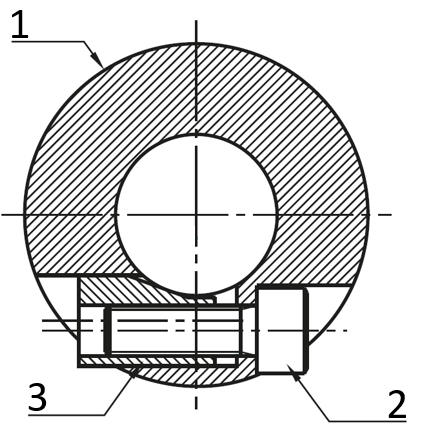

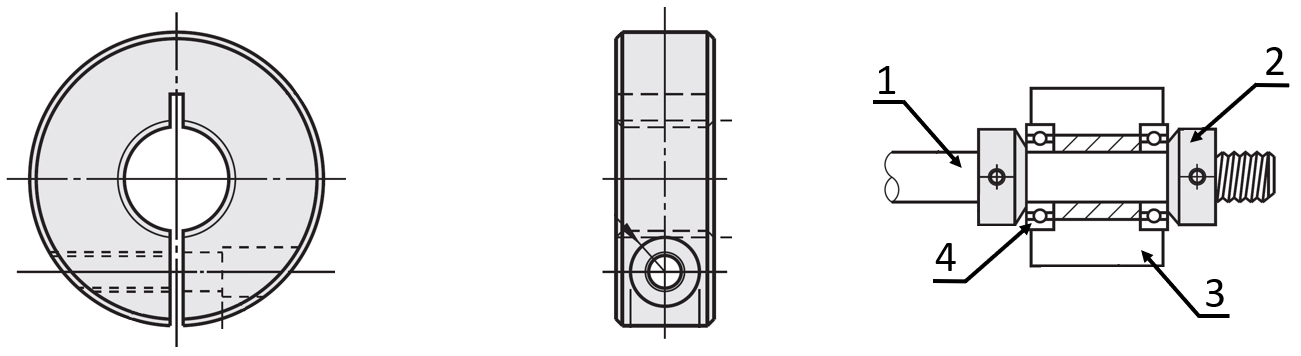

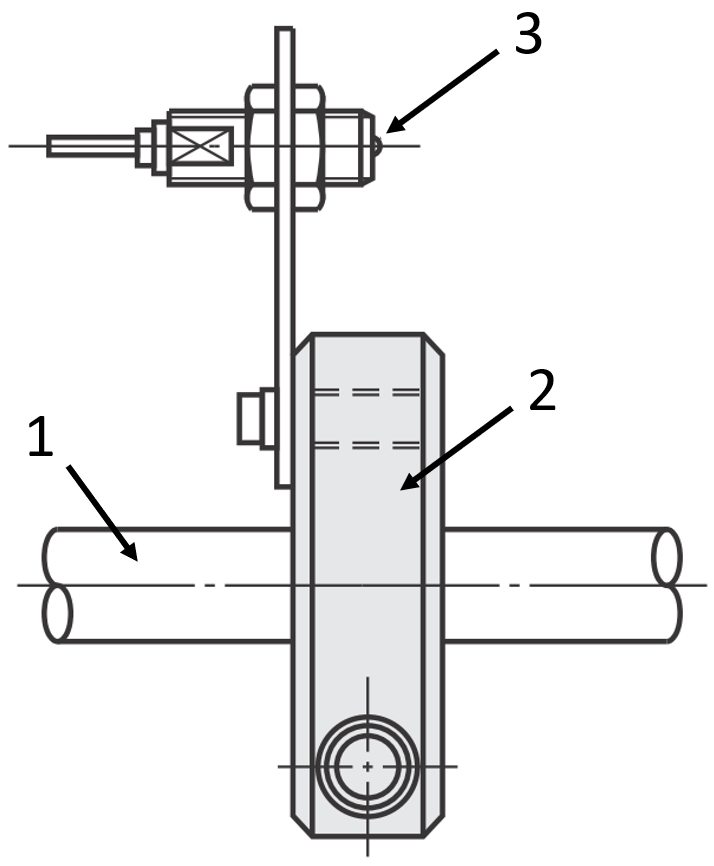

Application example: adjusting ring – (1) rotary shaft, (2) adjusting ring, (3) ball bearings

The appropriate adjusting ring should be selected depending on the application and the loads and forces that occur. MISUMI offers clamping rings in different types of clamping and sizes

Adjusting ring with set screw

The adjusting ring with set screw is the standard version of adjusting rings. In this variant, the adjusting ring is clamped to the set screw on the shaft.

In order to provide the adjusting ring with a good fit on the shaft with this type of clamping connection, it is often provided with a flat surface. This prevents any damage and deformations to the outer shaft part caused by the clamping pressure of the set screw. Another option to protect the outer part of the shaft is the utilization of a set screw with pins or a pressure piece made of a soft material (e.g., plastic, brass).

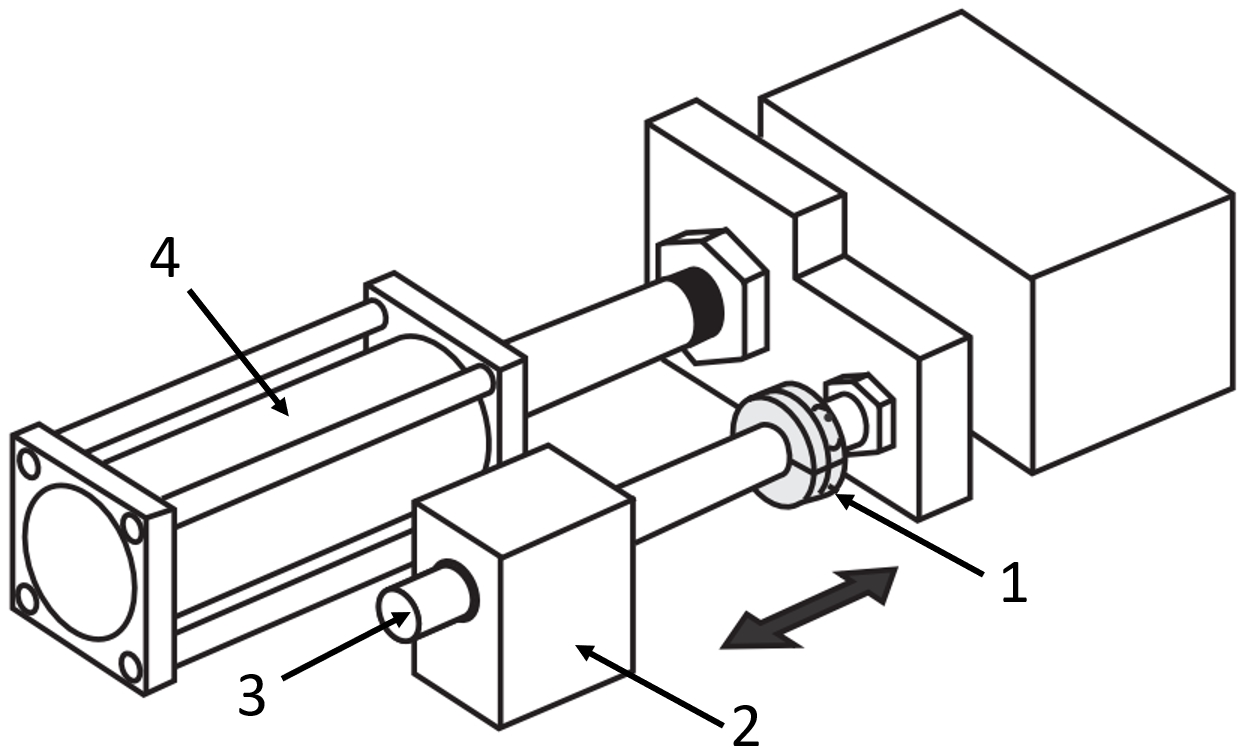

Application example: adjusting ring with set screw and set piece – (1) adjusting ring, (2) set screw, (3) set piece, (4) linear shaft

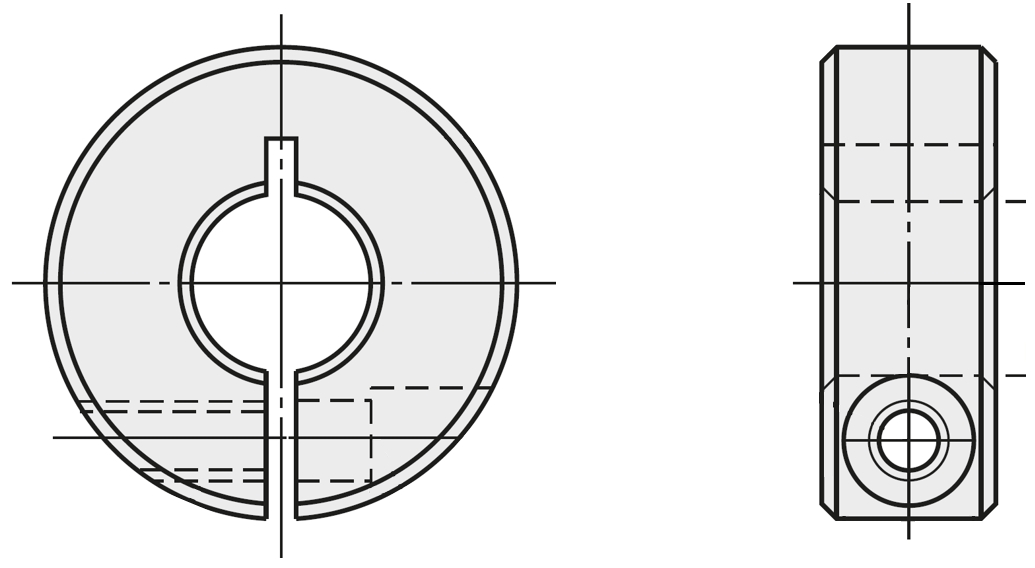

Clamping ring with a slot

The clamping ring with a slot is yet another, very common variant of adjusting rings. Its great advantage is that the clamping of the shaft exists over almost the entire contact surface of the clamping ring. This creates an evenly distributed clamping force, which reduces the risk of deformation or damage to the shaft. Bifurcated clamping rings can also create high clamping forces and ensure a stable fit of the clamping ring on the shaft. Since this type of clamping connection does not require a flat surface on the shaft for the clamping ring, the position of the clamping ring can be freely selected. This allows continuous adjustment on the shaft and the attachments (e.g., ball bearing, timing pulley).

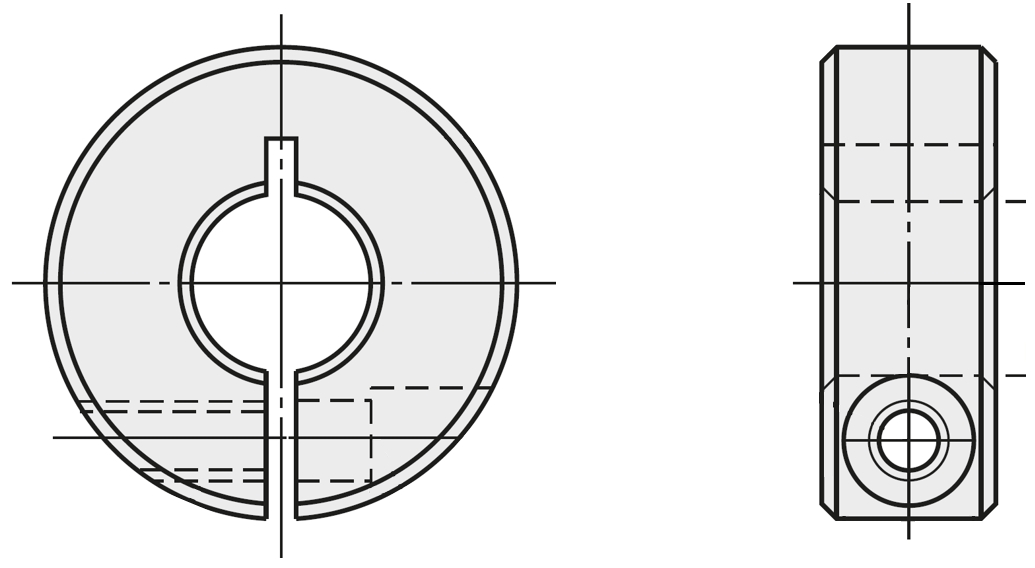

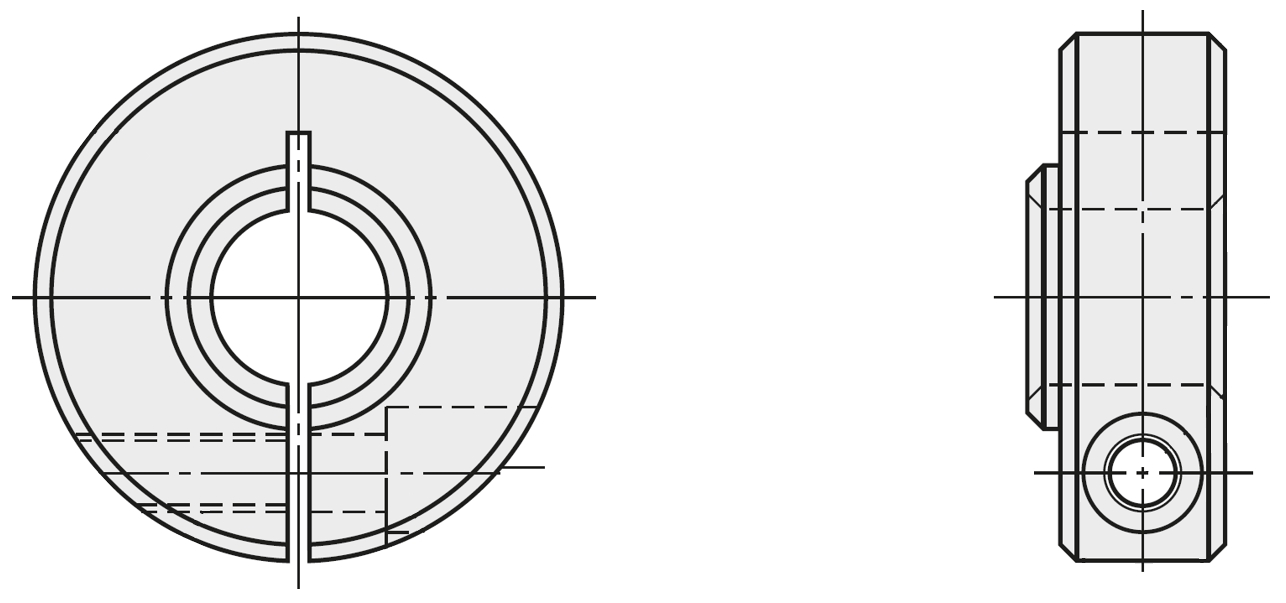

Drawing: clamping ring with slot

Adjusting ring with slot and clamping lever

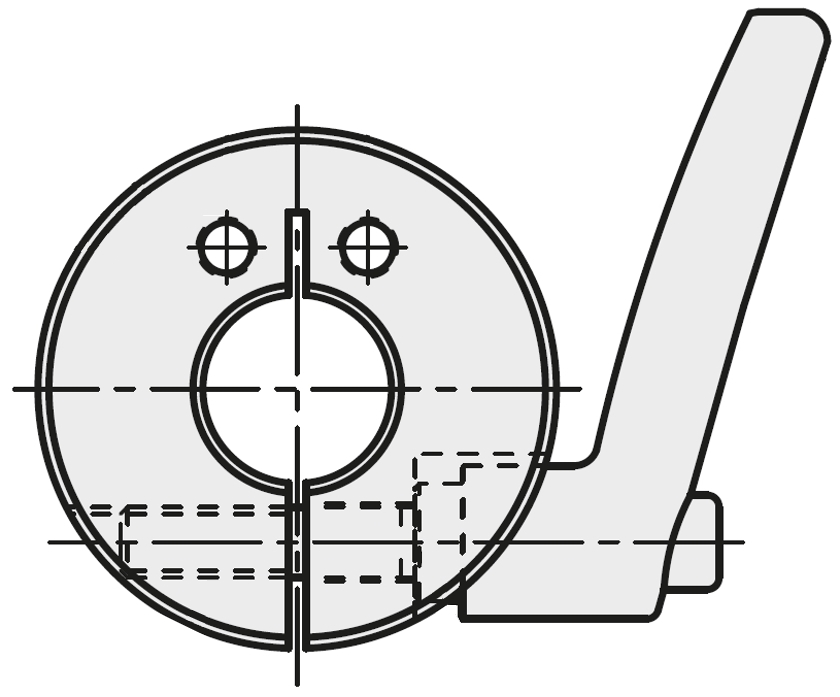

In applications where adjusting rings must be frequently adjusted, an adjusting ring with clamping lever can be used. This adjusting ring is identical in design to the slotted clamping ring, but it is equipped with a clamping lever that facilitates the fixing and loosening of the adjusting rings. Therefore, there is no additional tool required thanks to the clamping lever on the adjusting ring.

Drawing: clamping ring with clamping lever

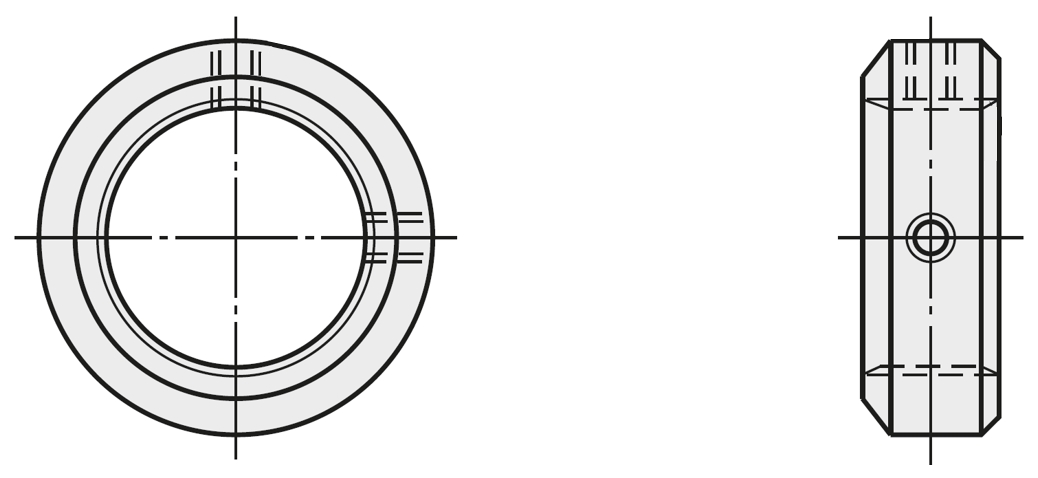

Adjusting ring with shoulder (for bearings)

The adjusting ring with shoulder is suitable for clamping ball bearings. The shoulder on the adjusting ring is clamped to the inner ring of the bearing. The adjusting ring with shoulder can thus rotate along the shaft while holding the bearing in the desired position.

Drawing: clamp ring with shoulder

Clamping ring with keyway

Clamping rings with a keyway are a special form of clamping ring as they allow the inclusion of keyways. This special form of adjusting ring enables clamping of timing pulleys or sprockets that are connected to the shaft with a parallel key. If a parallel key protrudes from the assembly part to be clamped, the clamping ring with a parallel key groove can receive the parallel key. This allows the clamping ring to lie flat with the component to be clamped. This makes it possible to maintain the necessary clamping force despite the parallel key.

Drawing: adjusting ring with keyway

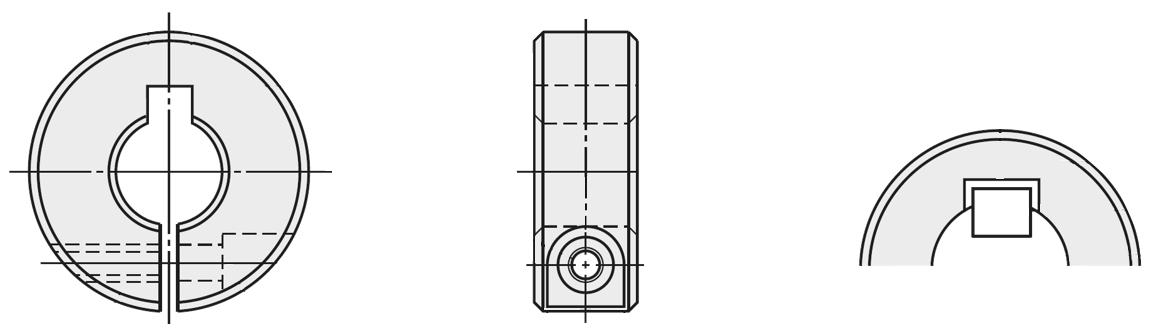

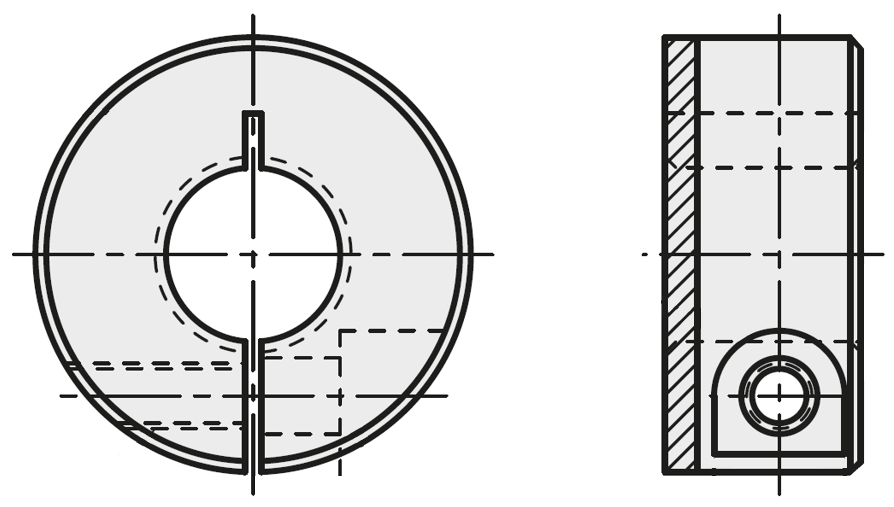

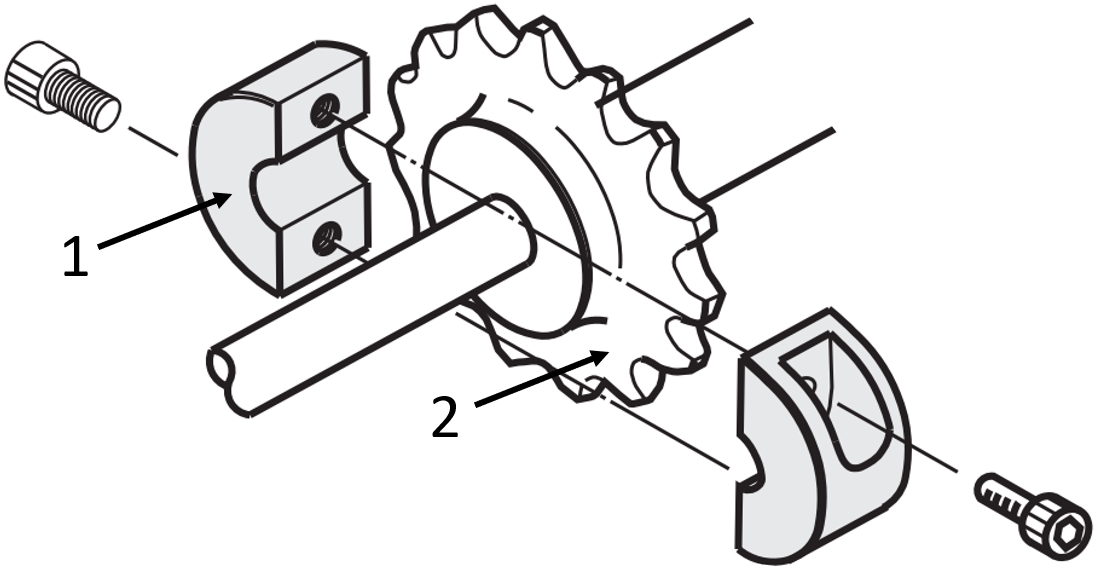

Two-part adjusting ring

These adjusting rings, in two-part design, are centrally split adjusting rings that create the clamping force with two screws and are thus mounted on the shaft.

This feature makes it easier to assemble and disassemble these adjusting rings during maintenance, especially in confined spaces, as the shaft does not have to be removed from the shaft holder during maintenance of the adjusting ring.

The split adjusting ring uses the entire contact surface for clamping, as well as the slotted clamping ring, and thus protects the shaft surface.

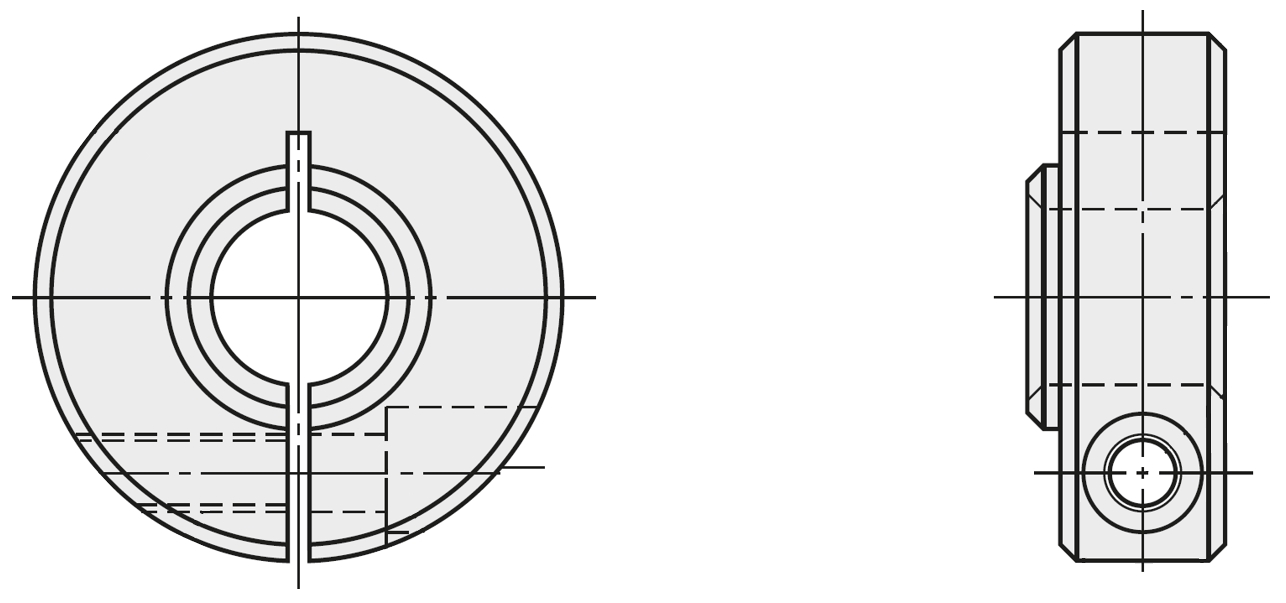

Drawing: two-part clamping ring

Two-part adjusting ring with slit and hinge

The two-part adjusting ring with hinge is a special variant of the adjusting rings. Like the two-part adjusting ring, this adjusting ring is also divided. However, in this variant, the upper part and lower part of the adjusting ring are connected to each other via a hinge.

This type of clamping facilitates assembly and disassembly of the adjusting ring compared to conventional clamping rings. Another benefit of the two-part adjusting rings with a hinge compared to the conventional two-part clamping rings is the reduced risk of loss during disassembly.

This adjusting ring is suitable for applications where the shaft should not be disassembled. The adjusting ring with hinge is particularly maintenance-friendly and can reduce the maintenance costs of an application.

Drawing: two-part clamping ring with hinge

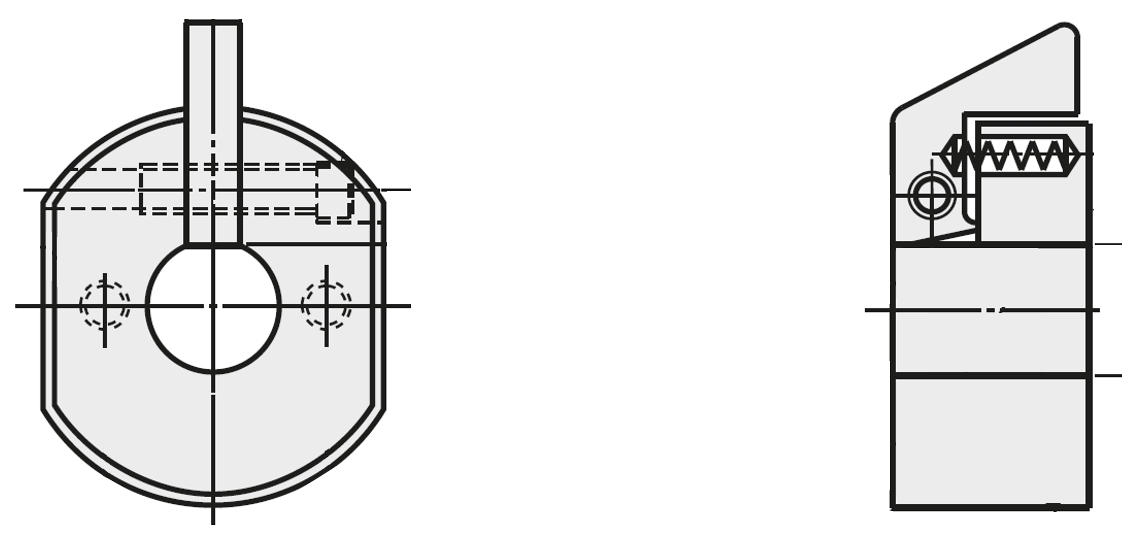

Clamping ring with wedge

The clamping ring with wedge is a special version of the adjusting rings. This adjusting ring uses an internal wedge for clamping, which presses the adjusting ring onto the shaft when the screw or lever is tightened.

A low tightening torque is necessary for clamping rings with a wedge, as this uses almost the entire contact surface for the clamping. Compared to an adjusting ring with a set screw, no flat surface is necessary and the risk of damage to the shaft is reduced. However, the wedge material should be softer than the shaft material to prevent deformation of the shaft.

Drawing: adjusting ring with wedge – (1) clamping ring, (2) screw, (3) wedge

Adjusting ring with quick-release fastener

MISUMI offers adjusting rings with a spring-loaded quick-release fastener for applications that frequently transition or require adjustment. This clamping ring uses spring force to clamp the shaft.

The spring installed in the clamping ring acts on the external operating lever, which is pressed onto the shaft and thus clamps the adjusting ring to the shaft. If the operating lever is actuated, the clamping force drops and the clamping ring can be released, removed or readjusted.

The clamping ring with quick-release fastener is particularly suitable for applications that require changing attachments frequently (e.g., unwinders). Adjusting rings with quick-release fasteners should not be used vertically, as they are not suitable for high axial forces.

Adjusting ring with quick-release fastener

Clamping ring with damper

For applications that require a damped stopper, the MISUMI clamping rings with dampers are an option that can reduce the assembly parts.

The clamping ring with damper is coated with polyurethane rubber, which acts as a damper in the event of an impact and is available in various types of Shore hardness at MISUMI. Therefore, it is not necessary to install a separate impact damper in an application.

Drawing: adjusting ring with damper

Female threaded adjusting ring

The female threaded adjusting ring is functionally similar to a shaft nut. However, a female threaded adjusting ring is additionally secured by a slotted clamp or a set screw. With this type of clamping function, a locking agent or another locknut is unnecessary with this type of adjusting ring.

The female threaded adjusting ring is available at MISUMI with standard metric threads and fine metric threads.

Drawing: female threaded clamping ring – (1) rotary shaft, (2) female threaded adjusting ring, (3) shaft holder, (4) ball bearings

Areas of Application

An adjusting ring, also called a clamping ring, can be used in many applications in various industries. MISUMI offers clamping rings in various basic forms and clamping types for positioning or as a stopper for various applications.

When using adjusting rings, further complex processing of the shafts can be dispensed with when form-locking clamps are used without the risk of damaging the shaft surface. Likewise, some of our clamp rings do not necessarily allow the shaft to be removed for maintenance, which can reduce maintenance costs.

Materials

MISUMI adjusting rings are made of aluminum, plastic, steel and stainless steel.

Coatings

MISUMI has adjusting rings available as uncoated, bronze-plated, nickel-plated, painted, anodized and LTBC-plated to protect them as much as possible from corrosion.

Dimensions

Round

Chamfered

Flattened on both sides

Flattened on one side

Cross hole

Offset

Installation Information

The maximum axial load of the adjusting rings depends on the clamping force generated. This is created by tightening the set screw, the clamping screw or the clamping lever. Therefore, it is important to maintain the correct tightening torque for the adjusting rings in order to ensure their correct function. The following test values are used for comparison, since the appropriate tightening torque depends on the corresponding application.

General note: The threads of the adjusting rings should be checked for damage after frequent tightening and loosening to ensure the required clamping force.

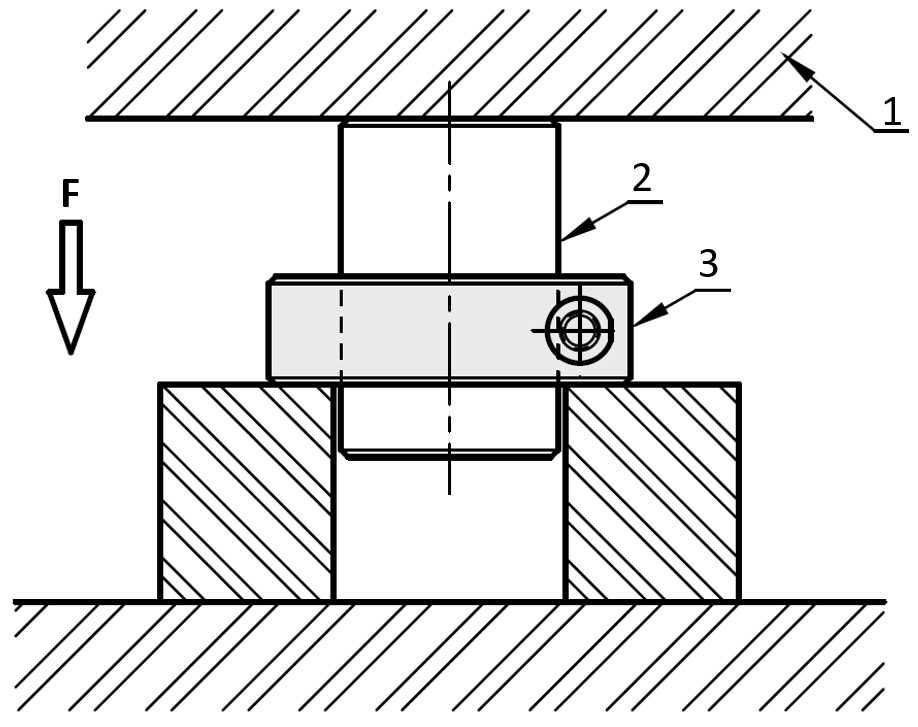

Drawing: test method design for clamping force – (1) test device, (2) linear shaft, (3) adjusting ring

[M] Thread diameter | Tightening torque (Nm) | |

EN 1.1191 equivalent/ | EN AW-2017 equivalent | |

M2.6 | 0.94 | - |

M3 | 1.61 | 1.61 |

M4 | 3.71 | 3.71 |

M5 | 7.54 | 7.54 |

M6 | 12.87 | 7.54 |

M8 | 31.2 | 12.87 |

M10 | 61.75 | 12.87 |

M16 | 267 | - |

Dimensions | Max. axial load (kN) | Weight (g) | |||

[D] Internal diameter | [W] Width | [M] Thread diameter | EN 1.1191 equivalent | EN 1.4301 equivalent | EN 1.1191 equivalent |

6 | *6 | 2.6 | 0,7 | 0,4 | 10 |

8 | 3 | 1,1 | 0,5 | 17 | |

10 | 4 | 1,8 | 1 | 21 | |

8 | *6 | 2.6 | 0,9 | 0,3 | 14 |

8 | 3 | 0,6 | 0,6 | 26 | |

10 | 4 | 2,2 | 1,1 | 32 | |

10 | *6 | 2.6 | 0,7 | 0,3 | 17 |

8 | 3 | 1,2 | 0,4 | 36 | |

10 | 4 | 2 | 1 | 45 | |

12 | 5 | 5,1 | 0,9 | 55 | |

12 | *6 | 2.6 | 0,7 | 0,3 | 16 |

8 | 3 | 1,1 | 0,8 | 34 | |

10 | 4 | 2,8 | 0,8 | 43 | |

12 | 5 | 4 | 1,2 | 52 | |

15 | *8 | 3 | 1,5 | 0,6 | 31 |

10 | 4 | 1,5 | 1,1 | 54 | |

12 | 5 | 5,1 | 1,8 | 69 | |

15 | 6 | 5,6 | 1,4 | 119 | |

16 | *8 | 3 | 2,1 | 1,1 | 29 |

10 | 5 | 7,1 | 2,9 | 55 | |

12 | 5 | 5,4 | 2,3 | 67 | |

15 | 6 | 10,2 | 1,5 | 116 | |

20 | *8 | 3 | 2,2 | 0,8 | 38 |

10 | 5 | 5,8 | 2,7 | 69 | |

12 | 5 | 6,4 | 1,7 | 84 | |

15 | 6 | 10,4 | 3 | 140 | |

25 | *10 | 4 | 3,6 | 1,8 | 66 |

12 | 5 | 8,8 | 2,6 | 98 | |

15 | 6 | 8,8 | 3,6 | 164 | |

30 | *12 | 5 | 8,4 | 2,8 | 111 |

15 | 6 | 8,9 | 2,2 | 185 | |

20 | 8 | 15 | 4 | 318 | |

35 | 15 | 6 | 9,9 | 2,7 | 207 |

40 | 18 | 8 | 21,3 | 6 | 348 |

50 | 22 | 10 | 35,8 | 11,8 | 604 |

Table axial load adjusting rings with slot

*Note: The axial load may differ from the determined data depending on the application. Dimensions marked with * only apply to the SCSJ, SSCSJ versions. All information is provided without guarantee.

[M] Thread diameter | Tightening torque (Nm) | |

EN 1.1191 Equiv. / | EN AW-2017 Equiv. | |

M2.6 | 0.94 | - |

M3 | 1.61 | 1.61 |

M4 | 3.71 | 3.71 |

M5 | 7.54 | 7.54 |

M6 | 12.87 | 7.54 |

M8 | 31.2 | 12.87 |

M10 | 61.75 | 12.87 |

M16 | 267 | - |

Mass | Max. Axial load (kN) | Weight (g) | |||

[D] Internal diameter | [B] Width | [M] Thread diameter | EN 1.1191 | EN 1.4301 Equiv. | EN 1.1191 |

10 | 10 | 4 | 1,6 | 1,2 | 29 |

12 | 10 | 4 | 2,2 | 1,4 | 35 |

15 | 10 | 4 | 1,8 | 1,5 | 37 |

16 | 12 | 5 | 3,0 | 2,3 | 57 |

20 | 12 | 5 | 3,5 | 3,0 | 69 |

25 | 12 | 5 | 3,5 | 3,2 | 88 |

30 | 12 | 5 | 3,2 | 3,2 | 94 |

35 | 15 | 6 | - | 3,1 | 154 |

40 | 15 | 8 | - | 3,1 | 243 |

50 | 15 | 8 | - | 3,1 | 299 |

*Note: The axial load may differ from the determined data depending on the application. All information is provided without guarantee.

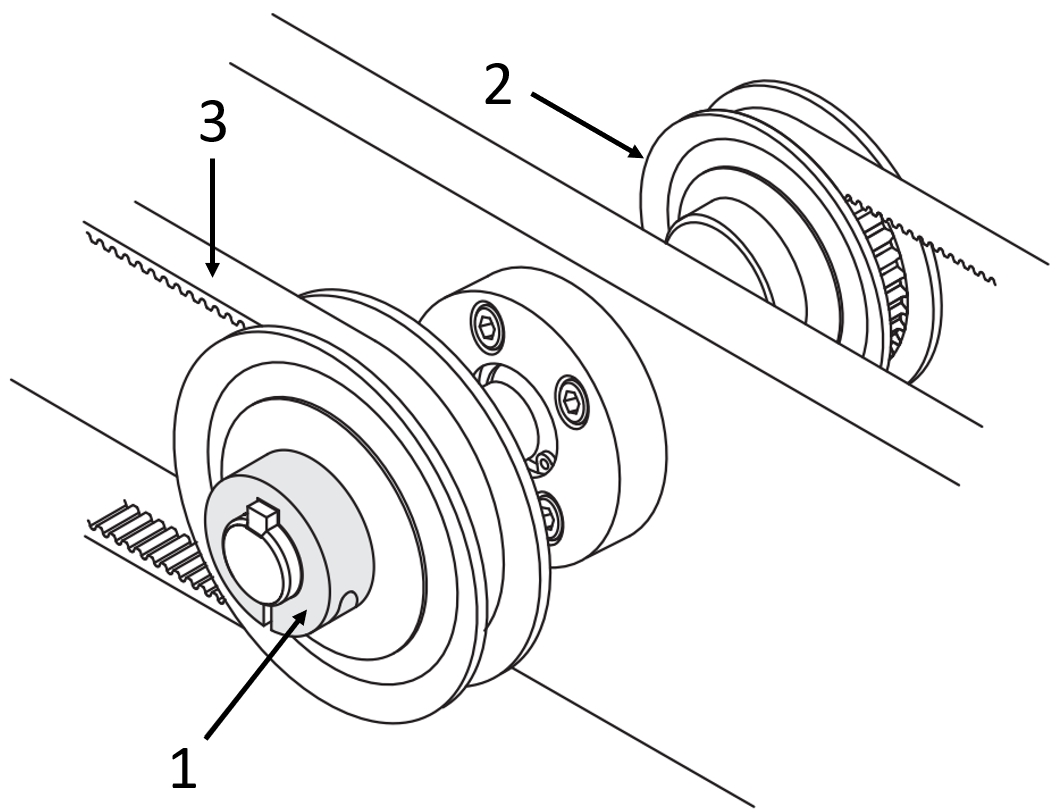

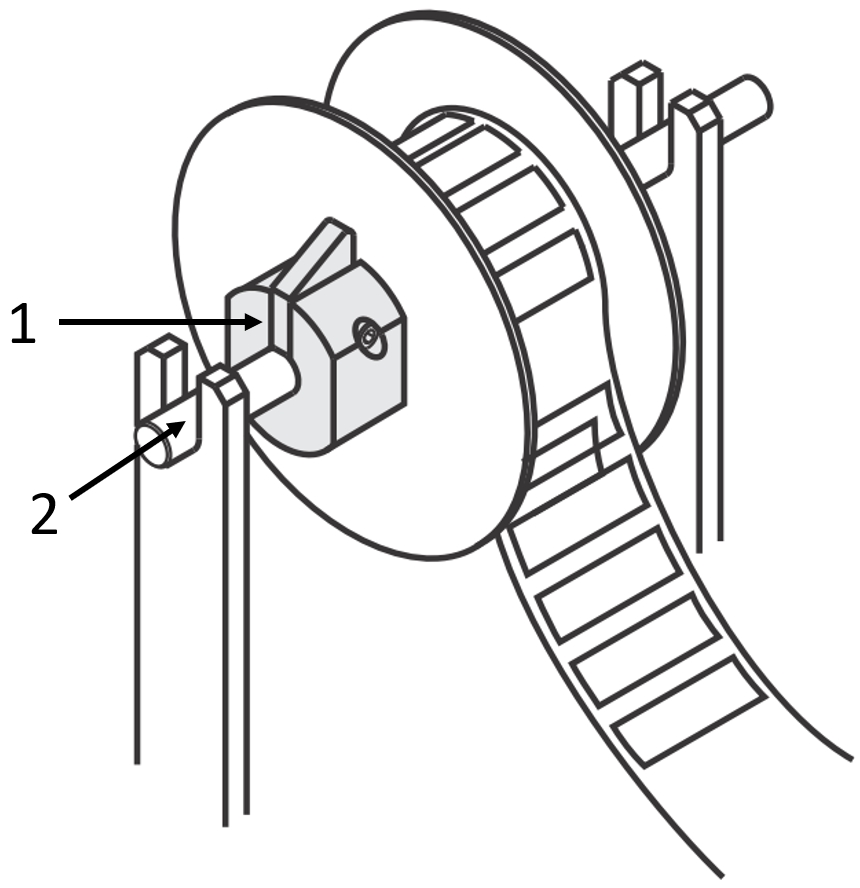

Application example Adjusting rings with keyway for timing pulleys

(1) Adjusting ring with keyway, (2) timing pulley, (3) timing belt

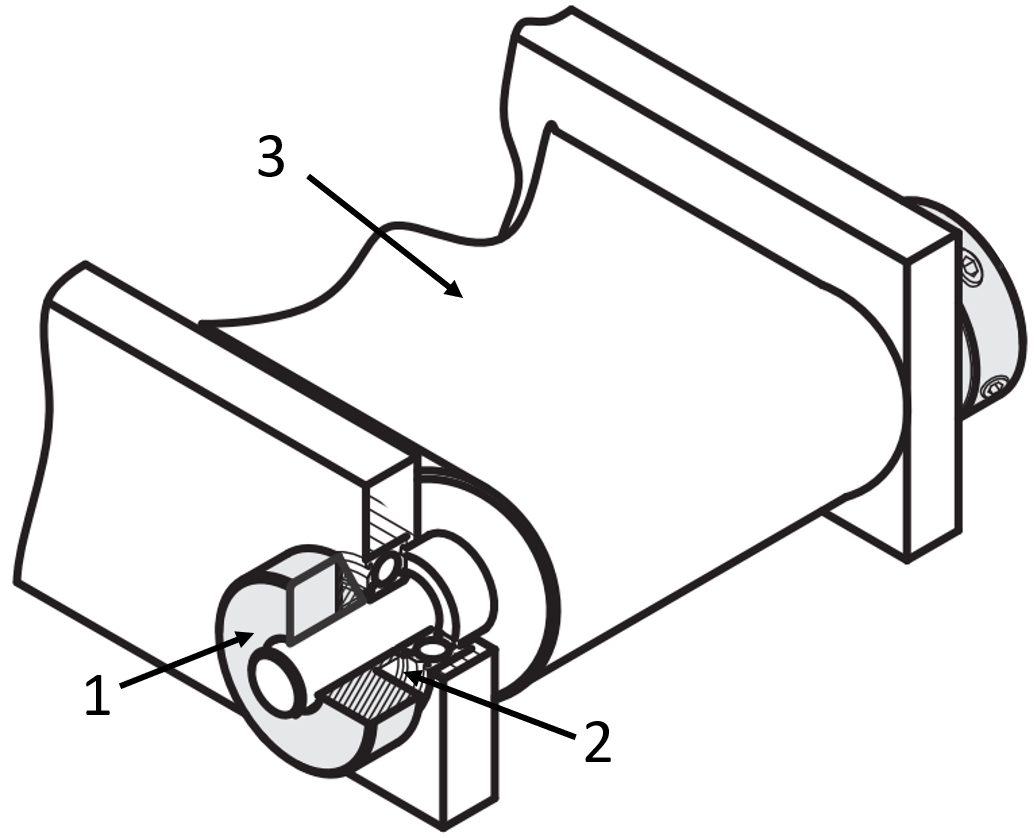

Application example Adjusting ring with shoulder for conveyor belt

(1) Adjusting ring with shoulder, (2) Ball bearing, (3) Flat belt

Application example split adjusting ring with chain wheel

(1) Two-piece adjusting ring, (2) Sprocket

Application example adjusting ring with damper

(1) Adjusting ring with damper, (2) Linear ball bearing block type, (3) Linear shaft, (4) Air cylinder

Application example clamping ring with quick release for unwinder

(1) clamping ring with quick release, (2) Rotary shaft

Application example clamping ring with cross hole for sensor

(1) Linear shaft, (2) clamping ring with cross hole, (3) contact switch

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| SSCSPB30-15 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | [D] Inner Diameter (mm) (mm) | O.D. (mm) | Width (mm) | Material | Surface Treatment | Thickness | Material | Surface Treatment | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

29.60 € | 1 | Available | 5 Days | 10 | 30 | 55 | 15 | EN 1.4301 Equiv. | No Surface Treatment | Balanced Type | EN 1.4301 Equiv. | Not Provided |

Loading...

Back to the Category Adjusting Rings

| D | B | D1 | M (Coarse) | d | R | X | Y | EN 1.1191 Equiv. | EN 1.4301 Equiv. | |||||||||||||||||||

| Black Oxide Coating | Electroless Nickel Plating | - | ||||||||||||||||||||||||||

| Standard | Compact | Balanced Type | Standard | Compact | Balanced Type | Standard | Compact | Balanced Type | Standard | Compact | Balanced Type | Standard | Compact | Balanced Type | Standard | Compact | Balanced Type | SCSP (Standard) | SCSPJ (Compact) | SCSPB (Balanced) | PSCSP (Standard) | PSCSPJ (Compact) | PSCSPB (Balanced) | SSCSP (Standard) | SSCSPJ (Compact) | SSCSPB (Balanced) | ||

| 3- | 8 | 16 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 4.5 | - | - | 2.2 | - | - | ● | - | - | ● | - | - | ● | - | - |

| 4- | 8 | 18 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 5 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - | - |

| 5- | 6 | - | 16 | - | - | M2.6 | - | - | 2.9 | - | - | 2.45 | - | - | 5.5 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 8 | 20 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 5.5 | - | - | 4 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10 | 22 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 6.5 | - | - | 4 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 6- | 6 | - | 18 | - | - | M2.6 | - | - | 2.9 | - | - | 2.45 | - | - | 6 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 8 | 20 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 6 | - | - | 4 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10 | 20 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 6 | - | - | 4 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 8- | 6 | - | 22 | - | - | M2.6 | - | - | 2.9 | - | - | 2.45 | - | - | 7 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 8 | 25 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 8 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10 | 25 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 8 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12 | 30 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 9 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 30 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 9 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10- | 6 | - | 25 | - | - | M2.6 | - | - | 2.9 | - | - | 2.45 | - | - | 8 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 8 | 30 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 9 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10 | 30 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 9 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12 | 30 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 10 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 35 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 10 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12- | 6 | - | 25 | - | - | M2.6 | - | - | 2.9 | - | - | 2.45 | - | - | 9 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 8 | 30 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 10 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 10 | 30 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 10 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12 | 30 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 10 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 35 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 11 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 13- | 8 | - | 28 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 11 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 10 | 30 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 10 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12 | 34 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 11 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 35 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 11 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15- | 8 | - | 30 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 11 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 10 | 34 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 11.5 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 12 | 35 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 12 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 40 | - | M6 | - | 6.6 | - | - | 6 | - | - | 13 | - | 8 | - | ● | - | - | ● | - | - | ● | - | - | |||||

| 16- | 8 | - | 30 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 11.5 | - | - | 3 | - | - | ● | - | - | ● | - | - | ● | - |

| 10 | 35 | - | 35 | M5 | - | M5 | 5.5 | - | 5.5 | 4.5 | - | 4.5 | 12 | - | 12 | 6 | - | 6 | ● | - | ● | ● | - | - | ● | - | - | |

| 12 | 35 | - | 35 | M5 | - | M5 | 5.5 | - | 5.5 | 4.5 | - | 4.5 | 12 | - | 12 | 6 | - | 6 | ● | - | - | ● | - | ● | ● | - | ● | |

| 15 | 40 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 13 | - | - | 8 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 17- | 10 | - | - | 40 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 14 | - | - | 7 | - | - | ● | - | - | ● | - | - | ● |

| 12 | - | - | 40 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 14 | - | - | 7 | - | - | ● | - | - | ● | - | - | ● | |

| 18- | 10 | 40 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 14 | - | - | 7 | - | - | ● | - | - | ● | - | - | ● | - | - |

| 12 | 40 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 14 | - | - | 7 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 15 | 45 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 15 | - | - | 8 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 20- | 8 | - | 35 | - | - | M3 | - | - | 3.4 | - | - | 3 | - | - | 13 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - |

| 10 | 40 | - | 40 | M5 | - | M5 | 5.5 | - | 5.5 | 4.5 | - | 4.5 | 14 | - | 14 | 7 | - | 7 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 12 | 40 | - | 40 | M5 | - | M5 | 5.5 | - | 5.5 | 4.5 | - | 4.5 | 14 | - | 14 | 7 | - | 7 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 15 | 45 | - | 45 | M6 | - | M6 | 6.6 | - | 6.6 | 6 | - | 6 | 15 | - | 15 | 8 | - | 8 | ● | - | ● | ● | - | - | ● | - | ● | |

| 25- | 10 | - | 42 | - | - | M4 | - | - | 4.5 | - | - | 3.75 | - | - | 16.5 | - | - | 5 | - | - | ● | - | - | ● | - | - | ● | - |

| 12 | 45 | - | 45 | M5 | - | M5 | 5.5 | - | 5.5 | 4.5 | - | 4.5 | 17 | - | 17 | 7 | - | 7 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 15 | 50 | - | 50 | M6 | - | M6 | 6.6 | - | 6.6 | 6 | - | 6 | 18 | - | 18 | 10 | - | 10 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 20 | 55 | - | - | M6 | - | - | 6.6 | - | - | 6 | - | - | 20 | - | - | 10 | - | - | ● | - | - | ● | - | - | ● | - | - | |

| 30- | 12 | - | 50 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 20 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - |

| 15 | 55 | - | 55 | M6 | - | M6 | 6.6 | - | 6.6 | 6 | - | 6 | 20 | - | 20 | 10 | - | 10 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 20 | 60 | - | 60 | M8 | - | M8 | 9 | - | 9 | 7 | - | 7 | 23 | - | 23 | 10 | - | 10 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 35- | 12 | - | 55 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 22.5 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - |

| 15 | 60 | - | 60 | M6 | - | M6 | 6.6 | - | 6.6 | 6 | - | 6 | 23 | - | 23 | 12 | - | 12 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 40- | 12 | - | 60 | - | - | M5 | - | - | 5.5 | - | - | 4.5 | - | - | 25 | - | - | 6 | - | - | ● | - | - | ● | - | - | ● | - |

| 18 | 70 | - | 70 | M8 | - | M8 | 9 | - | 9 | 7 | - | 7 | 26 | - | 26 | 13 | - | 13 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 50- | 18 | - | 80 | - | - | M8 | - | - | 9 | - | - | 7 | - | - | 32 | - | - | 15 | - | - | ● | - | - | ● | - | - | ● | - |

| 22 | 85 | - | 85 | M10 | - | M10 | 11 | - | 11 | 9 | - | 9 | 32 | - | 32 | 16 | - | 16 | ● | - | ● | ● | - | ● | ● | - | ● | |

| 60- | 22 | 95 | - | - | M10 | - | - | 11 | - | - | 9 | - | - | 37 | - | - | 18 | - | - | ● | - | - | ● | - | - | ● | - | - |

| 80- | 32 | 130 | - | - | M16 | - | - | 18 | - | - | 13 | - | - | 50 | - | - | 22 | - | - | ● | - | - | ● | - | - | - | - | - |

| 100- | 36 | 150 | - | - | M16 | - | - | 18 | - | - | 13 | - | - | 60 | - | - | 26 | - | - | ● | - | - | ● | - | - | - | - | - |

| D | W | ||

| Standard Type | Compact Type | Balanced Type | |

| 3 | 1 | - | - |

| 4 | 1 | - | - |

| 5 | 1 | 1 | - |

| 6 | 1 | 1 | - |

| 8 | 1.5 | 1.5 | - |

| 10 | 1.5 | 1.5 | - |

| 12 | 1.5 | 1.5 | - |

| 13 | 1.5 | 1.5 | - |

| 15 | 1.5 | 1.5 | - |

| 16 | 1.5 | 1.5 | 1.5 |

| 17 | - | - | 1.5 |

| 18 | 1.5 | - | - |

| 20 | 1.5 | 1.5 | 1.5 |

| 25 | 1.5 | 1.5 | 1.5 |

| 30 | 1.5 | 1.5 | 1.5 |

| 35 | 2 | 2 | 2 |

| 40 | 2 | 2 | 2 |

| 50 | 3 | 3 | 3 |

| 60 | 3 | - | - |

| 80 | 5 | - | - |

| 100 | 5 | - | - |

| D | B | D1 | M (Coarse) | d | R | X | Y | EN AW-2017 Equiv. | |

| - | Clear Anodize | ||||||||

| Standard | Standard | Standard | Standard | Standard | Standard | SCNPA (Standard) | SCNPAW (Standard) | ||

| 3- | 8 | 16 | M3 | 3.4 | 3 | 4.5 | 2.2 | ● | ● |

| 4- | 8 | 18 | M3 | 3.4 | 3 | 5 | 3 | ● | ● |

| 5- | 8 | 20 | M3 | 3.4 | 3 | 5.5 | 4 | ● | - |

| 6- | 8 | 20 | M3 | 3.4 | 3 | 6 | 4 | ● | ● |

| 8- | 8 | 25 | M3 | 3.4 | 3 | 7 | 5 | ● | ● |

| 10- | 10 | 30 | M4 | 4.5 | 3.75 | 9 | 5 | ● | ● |

| 12- | 10 | 30 | M4 | 4.5 | 3.75 | 10 | 5 | ● | ● |

| 13- | 10 | 30 | M4 | 4.5 | 3.75 | 10 | 5 | ● | ● |

| 15- | 10 | 34 | M4 | 4.5 | 3.75 | 11.5 | 6 | ● | ● |

| 16- | 10 | 35 | M5 | 5.5 | 4.5 | 12 | 6 | ● | ● |

| 20- | 10 | 40 | M5 | 5.5 | 4.5 | 14 | 7 | ● | ● |

| 25- | 12 | 45 | M5 | 5.5 | 4.5 | 17 | 7 | ● | ● |

| 30- | 15 | 55 | M6 | 6.6 | 6 | 20 | 10 | ● | ● |

| 35- | 15 | 60 | M6 | 6.6 | 6 | 23 | 12 | ● | ● |

| 40- | 18 | 70 | M8 | 9 | 7 | 26 | 13 | ● | ● |

| 50- | 22 | 85 | M10 | 11 | 9 | 32 | 16 | ● | ● |

| D | W |

| Standard | |

| 3 | 1 |

| 4 | 1 |

| 5 | 1 |

| 6 | 1 |

| 8 | 1.5 |

| 10 | 1.5 |

| 12 | 1.5 |

| 13 | 1.5 |

| 15 | 1.5 |

| 16 | 1.5 |

| 20 | 1.5 |

| 25 | 1.5 |

| 30 | 1.5 |

| 35 | 2 |

| 40 | 2 |

| 50 | 3 |

| Part Number | B | Body Weight (g) | Weight with Screws (g) | |||||

| Type | D | Top Half | Bottom Half | Weight Difference | Top Half | Bottom Half | Weight Difference | |

| SCSP (Standard) | 25 | 12 | 45 | 40 | 5 | 48 | 45 | 3 |

| 40 | 18 | 141 | 163 | 22 | 162 | 173 | 11 | |

| SCSPB (Balanced) | 25 | 12 | 43 | 43 | 0 | 47 | 47 | 0 |

| 40 | 18 | 152 | 152 | 0 | 167 | 167 | 0 | |

• Threads are coated with special plastic with excellent elasticity as well as resistance to abrasion and oil.

• Effect is maximum at the first use, and it will gradually decrease after the fourth use.

| D | Size Differences | Compact Type (P.272) | Standard | |||

| B (Thickness) | D1 (O.D.) | B (Thickness) | D1 (O.D.) | B (Thickness) | D1 (O.D.) | |

| 5 | -2 | -4 | 6 | 16 | 8 | 20 |

| 6 | -2 | -2 | 6 | 18 | 8 | 20 |

| 8 | -2 | -3 | 6 | 22 | 8 | 25 |

| 10 | -2 | -5 | 6 | 25 | 8 | 30 |

| 12 | -2 | -5 | 6 | 25 | 8 | 30 |

| 13 | -2 | -2 | 8 | 28 | 10 | 30 |

| 15 | -2 | -4 | 8 | 30 | 10 | 34 |

| 16 | -2 | -5 | 8 | 30 | 10 | 35 |

| 20 | -2 | -5 | 8 | 35 | 10 | 40 |

| 25 | -2 | -3 | 10 | 42 | 12 | 45 |

| 30 | -3 | -5 | 12 | 50 | 15 | 55 |

| 35 | -3 | -5 | 12 | 55 | 15 | 60 |

| 40 | -6 | -10 | 12 | 60 | 18 | 70 |

| 50 | -4 | -5 | 18 | 80 | 22 | 85 |

Basic information

| Tightening Method | Split | Specifications | Standard | Side Surface Machining | Not Provided |

|---|

This page is Set collars / aluminium, stainless steel, steel / two-piece, part number SSCSPB30-15.

You can find the detail information about specifications and dimensions on part number SSCSPB30-15.

Configure

Basic Attributes

-

Type

- PSCSP

- PSCSPB

- PSCSPJ

- SCNPA

- SCNPAW

- SCSP

- SCSPB

- SCSPJ

- SSCSP

- SSCSPB

- SSCSPJ

-

[D] Inner Diameter (mm)(mm)

-

O.D.(mm)

-

Width(mm)

-

Material

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

- Aluminum

-

Surface Treatment

- No Surface Treatment

- Surface Treatment Provided

-

Thickness

- Standard Type

- Compact Type

- Balanced Type

-

Material

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

- Aluminum Alloy 2000 series

-

Surface Treatment

- Black Oxide Coating

- Clear Anodize

- Electroless Nickel Plating

- Not Provided

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Variation of this product

| Part Number |

|---|

| PSCSP10-8 |

| PSCSP100-36 |

| PSCSP12-10 |

| SSCSPB30-20 |

| SSCSPB35-15 |

| SSCSPB40-18 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Standard Shipping Days ? | RoHS | [D] Inner Diameter (mm) (mm) | O.D. (mm) | Width (mm) | Material | Surface Treatment | Thickness | Material | Surface Treatment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

5.61 € | 1 | Available | 5 Days | 10 | 10 | 30 | 8 | EN 1.1191 Equiv. | [Surface Treatment Provided] Surface Treatment Provided | Standard Type | EN 1.1191 Equiv. | Electroless Nickel Plating | |

102.02 € | 1 | Available | 5 Days | 10 | 100 | 150 | 36 | EN 1.1191 Equiv. | [Surface Treatment Provided] Surface Treatment Provided | Standard Type | EN 1.1191 Equiv. | Electroless Nickel Plating | |

6.77 € | 1 | Available | 5 Days | 10 | 12 | 30 | 10 | EN 1.1191 Equiv. | [Surface Treatment Provided] Surface Treatment Provided | Standard Type | EN 1.1191 Equiv. | Electroless Nickel Plating | |

32.08 € | 1 | Available | 5 Days | 10 | 30 | 60 | 20 | EN 1.4301 Equiv. | No Surface Treatment | Balanced Type | EN 1.4301 Equiv. | Not Provided | |

35.77 € | 1 | Available | 5 Days | 10 | 35 | 60 | 15 | EN 1.4301 Equiv. | No Surface Treatment | Balanced Type | EN 1.4301 Equiv. | Not Provided | |

47.74 € | 1 | Available | 5 Days | 10 | 40 | 70 | 18 | EN 1.4301 Equiv. | No Surface Treatment | Balanced Type | EN 1.4301 Equiv. | Not Provided |

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry