- R Size(mm)

- 1.4

- Flute Length (ℓ)(mm)

- 3.5

- Overall Length (L)(mm)

- 40

- Shank Diameter (d)(mm)

- 4

- R Precision(μm)

- Inventory Classification

- Type

- Odhadované dodací dny

- Vše

- V rámci 5 pracovních dnů

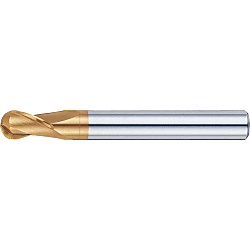

TSC series carbide ball end mill, short model (TSC-BEM2S1.4)

Obrysový výkres

Podrobné údaje

Základní informace

[Features]

-Good surface finish can be expected for the rough surface of the workpiece after machining

It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.

Specifikace a cena

Specifications

| Model Number | Shank Diameter d |

Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Under Neck Angle θ |

Figure | ||

| Tip R |

Shank Diameter d |

|||||||

| TSC-BEM2S | 0.05 | - | 3 | 0.2 | 0.1 | 40 | 10° | 1 |

| 0.1 | - | 3 | 0.4 | 0.2 | 40 | 10° | 1 | |

| 0.1 | 6 | 6 | 0.4 | 0.2 | 50 | 15° | 1 | |

| 0.15 | - | 3 | 0.6 | 0.3 | 40 | 10° | 1 | |

| 0.2 | - | 3 | 0.8 | 0.4 | 40 | 10° | 1 | |

| 0.2 | 6 | 6 | 0.8 | 0.4 | 50 | 15° | 1 | |

| 0.25 | - | 3 | 1 | 0.5 | 40 | 10° | 1 | |

| 0.3 | - | 3 | 1.2 | 0.6 | 40 | 10° | 1 | |

| 0.3 | 6 | 6 | 1.2 | 0.6 | 50 | 15° | 1 | |

| 0.35 | - | 3 | 1.4 | 0.7 | 40 | 10° | 1 | |

| 0.4 | - | 3 | 1.6 | 0.8 | 40 | 10° | 1 | |

| 0.4 | 6 | 6 | 1.6 | 0.8 | 50 | 15° | 1 | |

| 0.45 | - | 3 | 1.8 | 0.9 | 40 | 10° | 1 | |

| 0.5 | - | 4 | 2 | 1 | 40 | 10° | 1 | |

| 0.5 | 6 | 6 | 2 | 1 | 50 | 15° | 1 | |

| 0.55 | - | 4 | 2.2 | 1.1 | 40 | 10° | 1 | |

| 0.6 | - | 4 | 2.4 | 1.2 | 40 | 10° | 1 | |

| 0.65 | - | 4 | 2.6 | 1.3 | 40 | 10° | 1 | |

| 0.7 | - | 4 | 2.8 | 1.4 | 40 | 10° | 1 | |

| 0.75 | - | 4 | 3 | 1.5 | 40 | 10° | 1 | |

| 0.75 | 6 | 6 | 3 | 1.5 | 50 | 15° | 1 | |

| 0.8 | - | 4 | 3 | 1.6 | 40 | 10° | 1 | |

| 0.85 | - | 4 | 3 | 1.7 | 40 | 10° | 1 | |

| 0.9 | - | 4 | 3 | 1.8 | 40 | 10° | 1 | |

| 0.95 | - | 4 | 3 | 1.9 | 40 | 10° | 1 | |

| 1 | - | 4 | 3 | 2 | 40 | 10° | 1 | |

| 1 | 6 | 6 | 3 | 2 | 50 | 15° | 1 |

[ ! ]For shank diameter (d) specifications listed in blue, specify both a tip (R) and shank diameter (d).

| Model Number | Shank Diameter d |

Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Under Neck Angle θ |

Figure | ||

| Tip R |

Shank Diameter d |

|||||||

| TSC-BEM2S | 1.05 | - | 4 | 3 | 2.1 | 40 | 10° | 1 |

| 1.1 | - | 4 | 3 | 2.2 | 40 | 10° | 1 | |

| 1.15 | - | 4 | 3 | 2.3 | 40 | 10° | 1 | |

| 1.2 | - | 4 | 3 | 2.4 | 40 | 10° | 1 | |

| 1.25 | - | 4 | 3.5 | 2.5 | 40 | 10° | 1 | |

| 1.3 | - | 4 | 3.5 | 2.6 | 40 | 10° | 1 | |

| 1.4 | - | 4 | 3.5 | 2.8 | 40 | 10° | 1 | |

| 1.45 | - | 4 | 3.5 | 2.9 | 40 | 10° | 1 | |

| 1.5 | - | 4 | 4 | 3 | 40 | 10° | 1 | |

| 1.5 | 6 | 6 | 4 | 3 | 60 | 10° | 1 | |

| 1.55 | - | 4 | 4 | 3.1 | 40 | 10° | 1 | |

| 1.6 | - | 4 | 4 | 3.2 | 40 | 10° | 1 | |

| 1.65 | - | 4 | 4 | 3.3 | 40 | 10° | 1 | |

| 1.7 | - | 4 | 4 | 3.4 | 40 | 10° | 1 | |

| 1.75 | - | 4 | 5 | 3.5 | 40 | 10° | 1 | |

| 1.8 | - | 4 | 5 | 3.6 | 40 | 10° | 1 | |

| 1.85 | - | 4 | 5 | 3.7 | 40 | 10° | 1 | |

| 1.9 | - | 4 | 5 | 3.8 | 40 | 10° | 1 | |

| 2 | 4 | 4 | 6 | 4 | 50 | - | 2 | |

| 2 | - | 6 | 6 | 4 | 50 | 10° | 1 | |

| 2.15 | - | 6 | 6 | 4.3 | 50 | 10° | 1 | |

| 2.2 | - | 6 | 6 | 4.4 | 50 | 10° | 1 | |

| 2.3 | - | 6 | 6 | 4.6 | 50 | 10° | 1 | |

| 2.35 | - | 6 | 6 | 4.7 | 50 | 10° | 1 | |

| 2.4 | - | 6 | 6 | 4.8 | 50 | 10° | 1 | |

| 2.5 | - | 6 | 8 | 5 | 50 | 10° | 1 | |

| 2.6 | - | 6 | 8 | 5.2 | 50 | 10° | 1 | |

| 2.75 | - | 6 | 8 | 5.5 | 50 | 10° | 1 | |

| 3 | - | 6 | 10 | 6 | 60 | - | 2 | |

| 3.5 | - | 8 | 12 | 7 | 60 | 10° | 1 | |

| 4 | - | 8 | 13 | 8 | 60 | - | 2 | |

| 4.5 | - | 10 | 14 | 9 | 70 | 10° | 1 | |

| 5 | - | 10 | 15 | 10 | 80 | - | 2 | |

| 5.5 | - | 12 | 15 | 11 | 80 | 10° | 1 | |

| 6 | - | 12 | 15 | 12 | 80 | - | 2 | |

| 7 | - | 12 | 15 | 14 | 80 | - | 3 | |

| 8 | - | 16 | 20 | 16 | 150 | - | 2 | |

| 10 | - | 20 | 25 | 20 | 150 | - | 2 |

[ ! ]For shank diameter (d) specifications listed in blue, specify both a tip (R) and shank diameter (d).

For Cutting Conditions, Refer to >>Click here.

Funkce a příklady používání

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● Delivers a finish with a very good working surface roughness after machining.

[ ! ]The following additional processing services are available for the products on this page.