Překládáme náš obchod do češtiny!

Protože však máme mnoho produktů a stránek, bude to nějakou dobu trvat. Mezitím bude náš katalog produktů k dispozici v angličtině. Děkujeme vám za trpělivost!

Hinge Pins / Pivot Pins (Cleaning Method: Precision Cleaning)

At MISUMI, you will find highly configurable hinge pins in many geometric designs that can be customized to your needs.

Use our configurator to preselect your individual hinge bolt. Do you need help? Here you will find useful tutorials for using our configurator.

MISUMI offers a variety of configurable hinge bolts for a wide range of applications. Our knuckle pins can be selected in various geometries (external thread, internal thread, flat surface, hexagon socket, with shoulder, with flat shoulder, locking ring groove, cotter hole, spring groove, V-groove). Therefore, they are the right solution for many requirements. Our cotter bolts and hinge pins are available in stainless steel and steel and with various surface treatments burnished, hard chrome and nickel-plated. Our studs are available in diameters from 2 mm to 30 mm and in ISO tolerances g6, m6, p6, h7, f8, c9. The length of our hinge bolts ranges from 5 mm to 200 mm . Various types of mounting options are available for a configurable heavy duty hinge pin from MISUMI, which offer the appropriate protection for the hinge bolts according to the individual application. This includes threaded hinge pins withexternal thread or internal thread, flat surface, hexagon socket, shoulder, flattened shoulder, locking ring groove, cross-hole for cotter pin, spring groove, and a V-groove for mounting the hinge pin with a set screw.

Whether you need hinge bolts with split pins or bolts with heads, the MISUMI hinge pins offer many applications and a high usability in almost all industries.

| MISUMI offers you various helpful tools that can significantly shorten and simplify the design process. Here are some of the useful tools: | |||

meviy | Rapid-Design | FRAMES | Tech-Blog |

| On-Demand manufacturing via CAD data upload | Add-on for SOLIDWORKS | Software for aluminum profile design | Interesting articles |

![[Clean & Pack] Pivot Pin - Keys for Keyway Type](https://uk.misumi-ec.com/linked/material/mech/MSM1/PHOTO/110310641699_001.jpg)

- Volume Discount

MISUMI

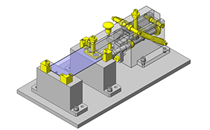

[Clean & Pack] Pivot Pin - Keys for Keyway Type

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□·Precision cleaning (Degassing double packing) : Part Number SH-□□·Electrolytic polishing + precision cleaning (Degassing double packing): Part Number SHD-□□Product Part NumberCleaning MethodPackaging TypeEffects Compared to Uncleaned ProductEnvironment (Standard)Possible applicationsSL-□□DegreasingAnti-rust packingOil removalGeneral environmentRegular assembly processPost battery assembly processSH-□□Precision cleaningDegassing double packingOil removalDust removalClean environment (Class 10 to 1,000*)Battery assembly processLCD-related post assembly processIn-vehicle camera assembly processSHD-□□Electrolytic polishing + precision cleaningDegassing double packingOil removalDust removalOutgas reductionVacuum environmentClean environment (Class 10 to 1,000*)Pre-semiconductor processLiquid crystal deposition processPre-OLED process*US FED STD 209E, ISO 14644-1 ISO 4 to ISO 6 Equiv. ■NotesCleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.Please be careful about the application location and storage environment.Více informacíBasic Shape RoHS Information Fastening Method Features, Areas of Application Shaft Dia. D(mm) L Dimension Configuration Type Material Hardness Surface Treatment Key RoHS Requirements Fulfilled Keyway Clean Washed ~ Non-magnetic - - Stainless Steel Not Specified Not Provided KonfigurovatCena (bez DPH) od:5.98 €Běžné datum odeslání:7 pracovních dnů