Překládáme náš obchod do češtiny!

Protože však máme mnoho produktů a stránek, bude to nějakou dobu trvat. Mezitím bude náš katalog produktů k dispozici v angličtině. Děkujeme vám za trpělivost!

Podmínky filtrování

- Nut type

- Straight

- Flange Type

- Compact Flanged

- Round Flanged

- Shaft O.D. D(φ)

- 6

- 8

- 10.4

- 13.4

- 16.6

- 20.6

- 25.8

- 30.8

- Shaft material

- Number of nuts(pcs.)

- 1

- 2

- Nut Overall Length(mm)

- 25

- 33

- 36

- 40

- 44

- 50

- 63

- 71

- 80

- Nut O.D.(φ)

- 14

- 16

- 21

- 24

- 31

- 35

- 42

- 47

- Shaft Overall Length L(mm)[60–1300/1mm jednotek]

- Nut Material

- Grease

- B(mm)[2–120/1mm jednotek]

- F(mm)[4–120/1mm jednotek]

- M(mm)

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 24

- N(mm)

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- P(mm)

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 13

- 15

- 16

- 20

- 25

- CAD

- 2D

- 3D

- Odhadované dodací dny

- Vše

- V rámci 9 pracovních dnů

- V rámci 10 pracovních dnů

- V rámci 11 pracovních dnů

- V rámci 12 pracovních dnů

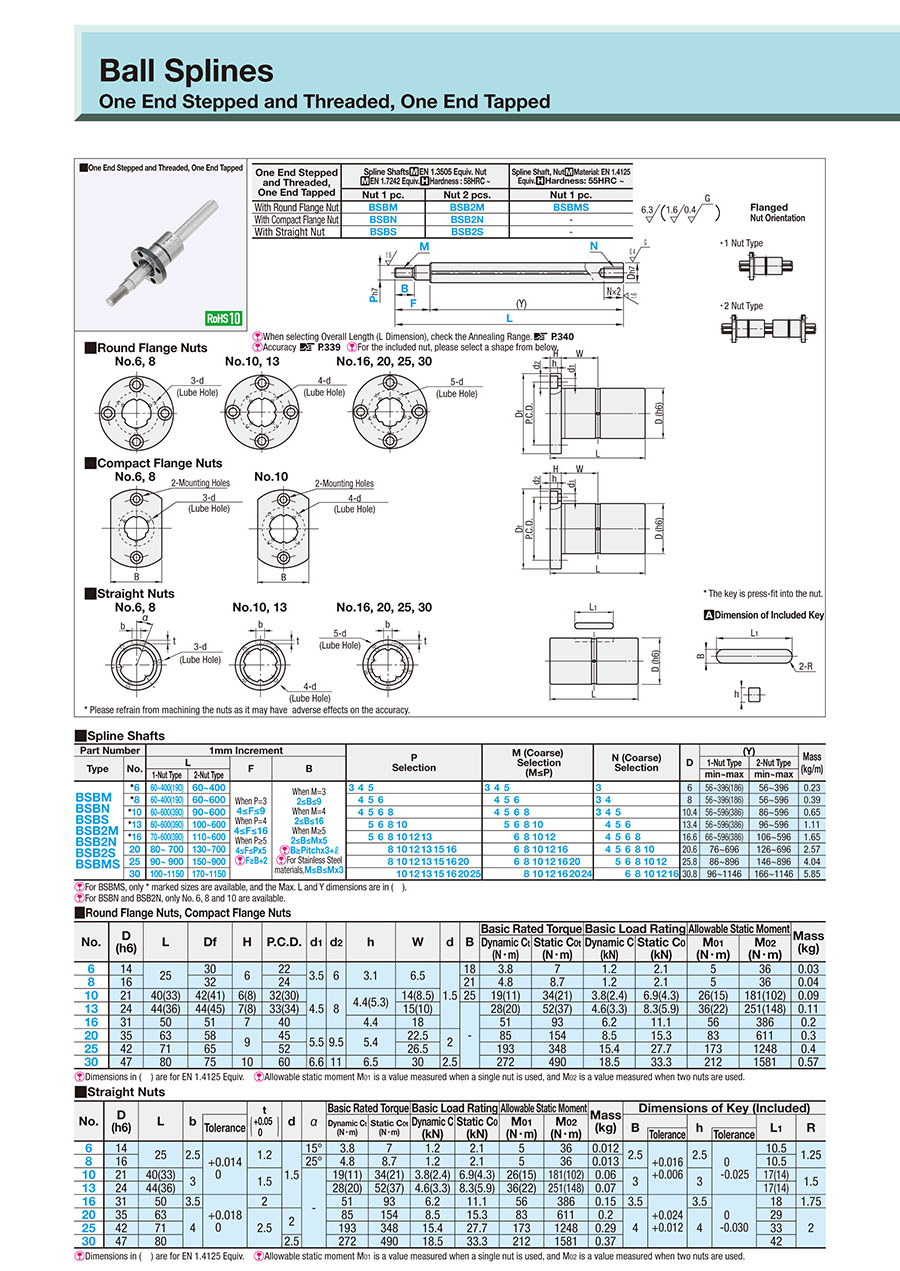

One End Threaded / One End Stepped and Threaded / One End Tapped(Seznam čísel dílů: stránka 3)

Klepnutím na obrázek zobrazíte zvětšený náhled

Pozor

- Please check the content on our website as the PDF does not contain the most up-to-date information.

Číslo dílu:

návrhy.Obrysový výkres a tabulka specifikací

| Flange type nut orientation ● 1-Nut Type | ● 2-Nut Type | |||||||||

|  | ||||||||||

| [ ! ] For the included nut, please select a shape from below. | |||||||||||

| Incomplete Thread Dimensions | |||||||||||

|

| ||||||||||

| ■Round Flanged |

|

| ■Compact Flanged |

|

| ■Straight Nuts | |

| [A]Dimension of Included Key |

[ ! ] Do not machine the nut as it will adversely affect accuracy.

[ ! ] The key is press fit into the nut.

| One End Stepped and Threaded, One End Tapped | Spline Shaft [M] EN 1.3505 Equiv., Nut [M] EN 1.7242 Equiv. [H]Hardness: 58HRC or more | Spline Shaft and Nut [M] Material: EN 1.4125 Equiv. [H]Hardness: 55 HRC or more | |

| Nut 1 pc. | Nut 2 pcs. | Nut 1 pc. | |

| With Round Flange Nut | BSBM | BSB2M | BSBMS |

| With Compact Flange Nut | BSBN | BSB2N | — |

| With Straight Nut | BSBS | BSB2S | BSBSS |

When specifying the nut mounting orientation, estimates for nonstandard products are used.

Specification Table

| Part Number | — | L | — | F | — | B | — | P | — | M | — | N |

BSB2N10 BSB2N10G BSB2N10G BSB2N10L BSB2N10L | — — — | 300 300 300 | — — — | F20 F20 F20 | — — — | B10 B10 B10 | — — — | P5 P5 P5 | — — — | M5 M5 M5 | — — — | N3 N3 N3 |

■Spline Shafts

[!] For BSBMS and BSBSS, only * marked sizes are available, and the Max. L and Y dimensions are in (). The pitch of the B dimension conditional expression is the pitch of M (Coarse)

[ ! ] For BSBN and BSB2N, only No. 6, 8 and 10 are available.

■Round Flange Nuts, Compact Flange Nuts

[!] Dimensions in () are for EN 1.4125 Equiv. [!] Allowable static moment M01 are values measured when a single nut is used, and M02 are values measured when two nuts are used in contact.

■Straight Nuts

[!] Dimensions in () are for EN 1.4125 Equiv. [!] Allowable static moment M01 are values measured when a single nut is used, and M02 are values measured when two nuts are used in contact.

| Part Number | 1 mm Increments | P Selection | M (Coarse) Selection (M ≤ P) | N (Coarse) Selection | D | (Y) | Mass (kg/m) | ||||||||||||||||||||||||||||||||

| Type | No. | L | F | B | 1-Nut Type | 2-Nut Type | |||||||||||||||||||||||||||||||||

| 1-Nut Type | 2-Nut Type | Min to Max | Min to Max | ||||||||||||||||||||||||||||||||||||

| BSBM BSBN BSBS BSB2M BSB2N BSB2S BSBMS BSBSS | * 6 | 60 to 500 (190) | 60 to 500 | When P = 3 4 ≤ F ≤ 9 When P = 4 4 ≤ F ≤ 16 When P ≥ 5 4 ≤ F ≤ P × 5 [ ! ]F ≥ B+2 | When M = 3 2 ≤ B ≤ 9 When M = 4 2 ≤ B ≤ 16 When M ≥ 5 2 ≤ B ≤ M × 5 [ ! ]B ≥ Pitch × 3 + ℓ [ ! ] For Stainless Steel material, M ≤ B ≤ M × 3 | 3 | 4 | 5 | 3 | 4 | 5 | 3 | 6 | 56 to 396 (186) | 56 to 396 | 0.23 | |||||||||||||||||||||||

| * 8 | 60 to 600 (190) | 60 to 600 | 4 | 5 | 6 | 4 | 5 | 6 | 3 | 4 | 8 | 56 to 396 (186) | 56 to 596 | 0.39 | |||||||||||||||||||||||||

| * 10 | 60 to 800 (390) | 90 to 800 | 4 | 5 | 6 | 8 | 4 | 5 | 6 | 8 | 3 | 4 | 5 | 10.4 | 56 to 596 (386) | 86 to 596 | 0.65 | ||||||||||||||||||||||

| * 13 | 60 to 800 (390) | 100 to 800 | 5 | 6 | 8 | 10 | 5 | 6 | 8 | 10 | 4 | 5 | 6 | 13.4 | 56 to 596 (386) | 96 to 596 | 1.11 | ||||||||||||||||||||||

| * 16 | 70 to 1000 (390) | 110 to 1000 | 5 | 6 | 8 | 10 | 12 | 13 | 6 | 8 | 10 | 12 | 4 | 5 | 6 | 8 | 16.6 | 66 to 596 (386) | 106 to 596 | 1.65 | |||||||||||||||||||

| 20 | 80 to 1000 | 130 to 1000 | 8 | 10 | 12 | 13 | 15 | 16 | 6 | 8 | 10 | 12 | 16 | 4 | 5 | 6 | 8 | 10 | 20.6 | 76 to 696 | 126 to 696 | 2.57 | |||||||||||||||||

| 25 | 90 to 1300 | 150 to 1300 | 8 | 10 | 12 | 13 | 15 | 16 | 20 | 6 | 8 | 10 | 12 | 16 | 20 | 5 | 6 | 8 | 10 | 12 | 25.8 | 86 to 896 | 146 to 896 | 4.04 | |||||||||||||||

| 30 | 100 to 1300 | 170 to 1300 | 10 | 12 | 13 | 15 | 16 | 20 | 25 | 8 | 10 | 12 | 16 | 20 | 24 | 6 | 8 | 10 | 12 | 16 | 30.8 | 96 to 1146 | 166 to 1146 | 5.85 | |||||||||||||||

[ ! ] For BSBN and BSB2N, only No. 6, 8 and 10 are available.

■Round Flange Nuts, Compact Flange Nuts

| No. | D (h6) | L | df | H | P.C.D. | d1 | d2 | h | W | d | B | Basic Rated Torque | Basic Load Rating | Allowable Static Moment | Mass (kg) | |||

| Dynamic Ct (N⋅m) | Static C0 t (N⋅m) | Dynamic C (kN) | Static C0 (kN) | M01 (N⋅m) | M02 (N⋅m) | |||||||||||||

| 6 | 14 | 25 | 30 | 6 | 22 | 3.5 | 6 | 3.1 | 6.5 | 1.5 | 18 | 3.8 | 7 | 1.2 | 2.1 | 5 | 36 | 0.03 |

| 8 | 16 | 32 | 24 | 21 | 4.8 | 8.7 | 1.2 | 2.1 | 5 | 36 | 0.04 | |||||||

| 10 | 21 | 40 (33) | 42 (41) | 6 (8) | 32 (30) | 4.5 | 8 | 4.4 (5.3) | 14 (8.5) | 25 | 19 (11) | 34 (21) | 3.8 (2.4) | 6.9 (4.3) | 26 (15) | 181 (102) | 0.09 | |

| 13 | 24 | 44 (36) | 44 (45) | 7 (8) | 33 (34) | 15 (10) | — | 28 (20) | 52 (37) | 4.6 (3.3) | 8.3 (5.9) | 36 (22) | 251 (148) | 0.11 | ||||

| 16 | 31 | 50 | 51 | 7 | 40 | 4.4 | 18 | 51 | 93 | 6.2 | 11.1 | 56 | 386 | 0.2 | ||||

| 20 | 35 | 63 | 58 | 9 | 45 | 5.5 | 9.5 | 5.4 | 22.5 | 2 | 85 | 154 | 8.5 | 15.3 | 83 | 611 | 0.3 | |

| 25 | 42 | 71 | 65 | 52 | 26.5 | 193 | 348 | 15.4 | 27.7 | 173 | 1248 | 0.4 | ||||||

| 30 | 47 | 80 | 75 | 10 | 60 | 6.6 | 11 | 6.5 | 30 | 2.5 | 272 | 490 | 18.5 | 33.3 | 212 | 1581 | 0.57 | |

■Straight Nuts

| No. | D (h6) | L | b | t (+0.05 0) | d | α | Basic Rated Torque | Basic Load Rating | Allowable Static Moment | Mass (kg) | Dimensions of Key (Included) | |||||||||

| Tolerance | Dynamic Ct (N⋅m) | Static C0 t (N⋅m) | Dynamic C (kN) | Static C0 (kN) | M01 (N⋅m) | M02 (N⋅m) | B | h | L1 | R | ||||||||||

| Tolerance | Tolerance | |||||||||||||||||||

| 6 | 14 | 25 | 2.5 | +0.014 0 | 1.2 | 1.5 | 15° | 3.8 | 7 | 1.2 | 2.1 | 5 | 36 | 0.012 | 2.5 | +0.016 +0.006 | 2.5 | 0 −0.025 | 10.5 | 1.25 |

| 8 | 16 | 25° | 4.8 | 8.7 | 1.2 | 2.1 | 5 | 36 | 0.013 | 10.5 | ||||||||||

| 10 | 21 | 40 (33) | 3 | 1.5 | — | 19 (11) | 34 (21) | 3.8 (2.4) | 6.9 (4.3) | 26 (15) | 181 (102) | 0.06 | 3 | 3 | 17 (14) | 1.5 | ||||

| 13 | 24 | 44 (36) | 28 (20) | 52 (37) | 4.6 (3.3) | 8.3 (5.9) | 36 (22) | 251 (148) | 0.07 | 17 (14) | ||||||||||

| 16 | 31 | 50 | 3.5 | +0.018 0 | 2 | 51 | 93 | 6.2 | 11.1 | 56 | 386 | 0.15 | 3.5 | +0.024 +0.012 | 3.5 | 0 −0.030 | 18 | 1.75 | ||

| 20 | 35 | 63 | 4 | 2.5 | 2 | 85 | 154 | 8.5 | 15.3 | 83 | 611 | 0.2 | 4 | 4 | 29 | 2 | ||||

| 25 | 42 | 71 | 193 | 348 | 15.4 | 27.7 | 173 | 1248 | 0.29 | 33 | ||||||||||

| 30 | 47 | 80 | 2.5 | 272 | 490 | 18.5 | 33.3 | 212 | 1581 | 0.37 | 42 | |||||||||

Alterations

| Part Number | — | L | — | F | — | B | — | P | — | M | — | N | — | (SC·FC) |

| BSB2N10 | — | 300 | — | F20 | — | B10 | — | P5 | — | M5 | — | N3 | — | SC15 |

| Alterations | Wrench Flats | Set Screw Flat | |||||||||||||||||||||||||||||||||||||||||

|  | ||||||||||||||||||||||||||||||||||||||||||

| Code | SC | FC | |||||||||||||||||||||||||||||||||||||||||

| Spec. |

|

| |||||||||||||||||||||||||||||||||||||||||

[ ! ] It is not possible to specify the key of the spline nut or the positional relationship between the mounting hole and alteration.

Seznam čísel dílů

| Číslo dílu |

|---|

Jednotková cena (bez DPH)(Jednotková cena včetně DPH) | Standardní datum odeslání |

|---|

- ( - ) | 10 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 10 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 10 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 12 pracovních dnů |

- ( - ) | 9 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 9 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 9 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 9 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 9 pracovních dnů |

- ( - ) | 11 pracovních dnů |

- ( - ) | 11 pracovních dnů |

Podrobné údaje

Základní informace

Pozor

- Please check the content on our website as the PDF does not contain the most up-to-date information.

Náčrt a specifikace

Specifications/Overview

| Precautions for Ball Spline Assembly |  |

| ■Check Assembly Position | |

| Match Mark Numbers are entered on nuts and spline shafts (see the diagram on the right). | |

| When re-assembling, confirm the match mark numbers, character orientations, and positional relationship of parts. | |

| If the alignment marks are not aligned correctly, the function will be affected. | |

| ■Tolerance for Mating Bores | |

| H7 tolerance is recommended for mating bores for the spline nuts when mounting them on housings. | |

| ■For Customers machining the shaft ends | |

| In order to facilitate nut insertions, chamfer the machined shaft ends, and remove burrs on the edges of the spline groove with a round file. |