- inCAD Library Home

- > No.000108 Linear Movement Mechanism

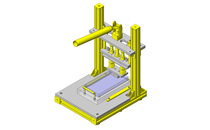

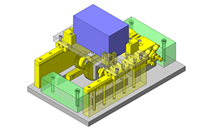

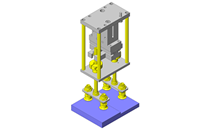

No.000108 Linear Movement Mechanism

46

46

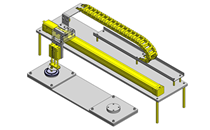

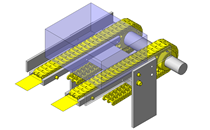

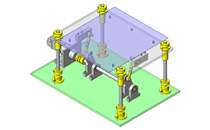

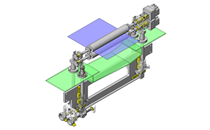

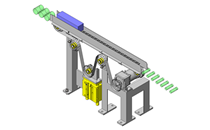

Slowly strokes for a short distance.

Related Category

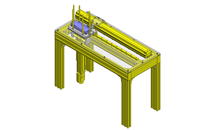

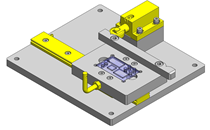

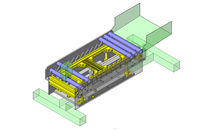

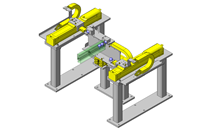

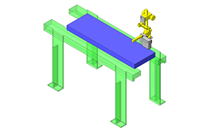

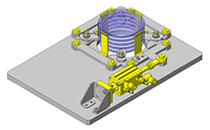

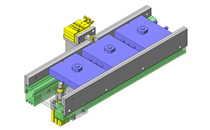

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

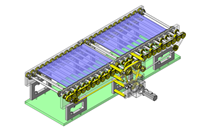

Application Overview

Purpose

- Purpose

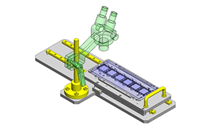

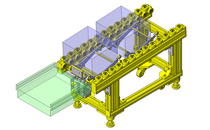

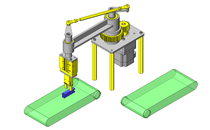

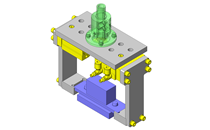

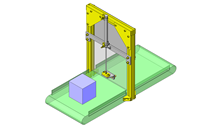

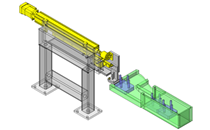

- Jack for switching mold type.

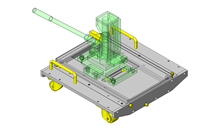

- Operation

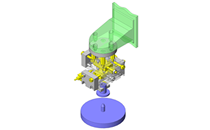

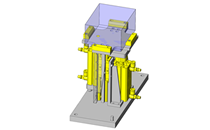

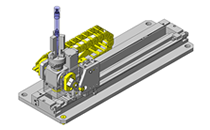

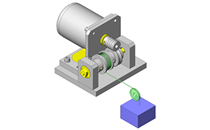

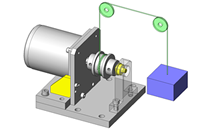

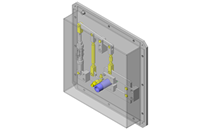

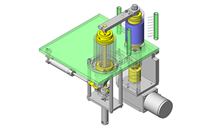

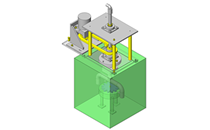

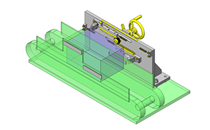

- Rotary movement is converted into linear movement. By rotating the rotary actuator by 180°, the lead screw is rotated. The nut on the lead screw makes linear movements to move up and down.

Points for use

- A heavy load is slowly raised a short distance. A rotary actuator is used as the drive source.

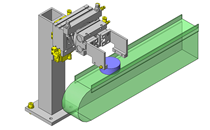

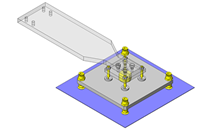

Target workpiece

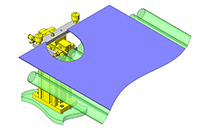

- Mold for lead frame

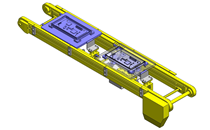

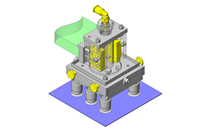

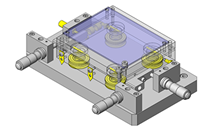

- Size: W180 x D310 x H214mm

- Weight: 34kg

Design Specifications

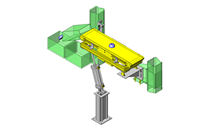

Operating Conditions or Design Requirements

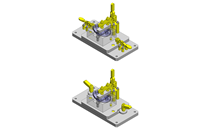

- Ascending/descending stroke: 2.5mm

- Safety factor: S = 1.7

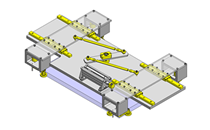

- Outer dimensions: W180 x D400 x H262mm

Required Performance

- Positioning accuracy: ±0.05mm

- Upward thrust: 580N

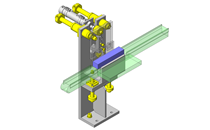

Selection Criteria for Main Components

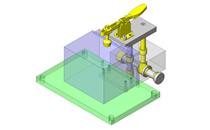

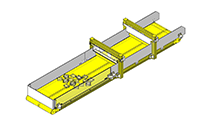

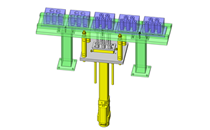

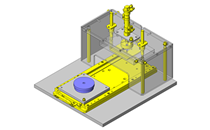

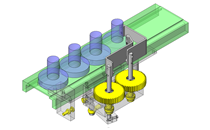

- Lead Screw

- As the ascending/descending stroke is 2.5 mm, a 5-mm lead is selected as its multiple number lead.

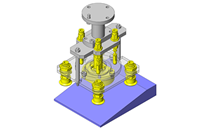

- Rotary actuator

- A rotary actuator with an oscillation angle of 180° and a torque of 1.7 [N・m] (0.5 MPa) or higher is selected.

Design Evaluation

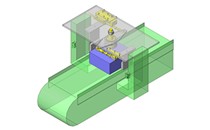

Verification of main components

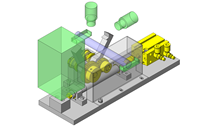

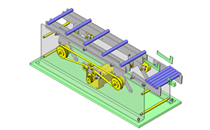

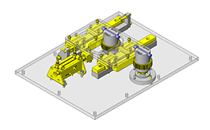

- Whether an appropriate thrust for raising the workpiece can be obtained is verified based on the specifications of the rotary actuator and the lead screw.

- Calculation of upward thrust

- Conditional value: workpiece mass W = 55kg, gravitational acceleration g = 9.8m/s², friction coefficient μ = 0.21, lead of lead screw R = 5mm, lead angle d = 4°40' = 4.67°, rotary actuator torque T = 1.863N・m = 186.3N・cm

Screw efficiency: η = (1 - μ x tan(d))/(1 + μ/tan(d))

= (1 - 0.21 x tan4.67°)/(1 + 0.21/tan4.67°)

= 0.275

Upward thrust F = (2π x η x T)/R

= (2π x 0.275 x 186.3)/0.5

= 644N

- Conditional value: workpiece mass W = 55kg, gravitational acceleration g = 9.8m/s², friction coefficient μ = 0.21, lead of lead screw R = 5mm, lead angle d = 4°40' = 4.67°, rotary actuator torque T = 1.863N・m = 186.3N・cm

Explore Similar Application Examples

Page

-

/

-